For product information and pricing, Chat with sales agent:

or email us : sales@clirik.com

Click links below to see related products.

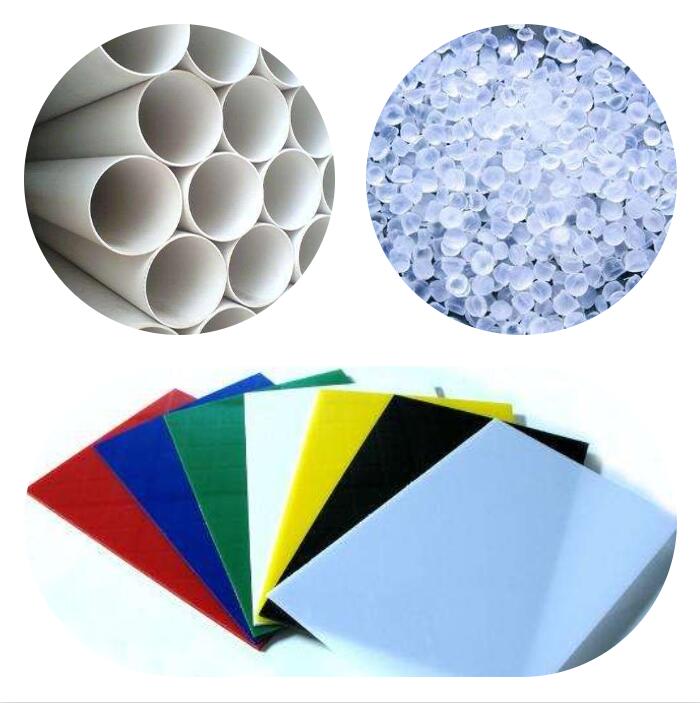

Calcium carbonate has a wide range of uses, and it is also widely used in PVC products, such as PVC pipes, PVC resin tiles, PVC doors and windows, PVC edge strips, and so on.

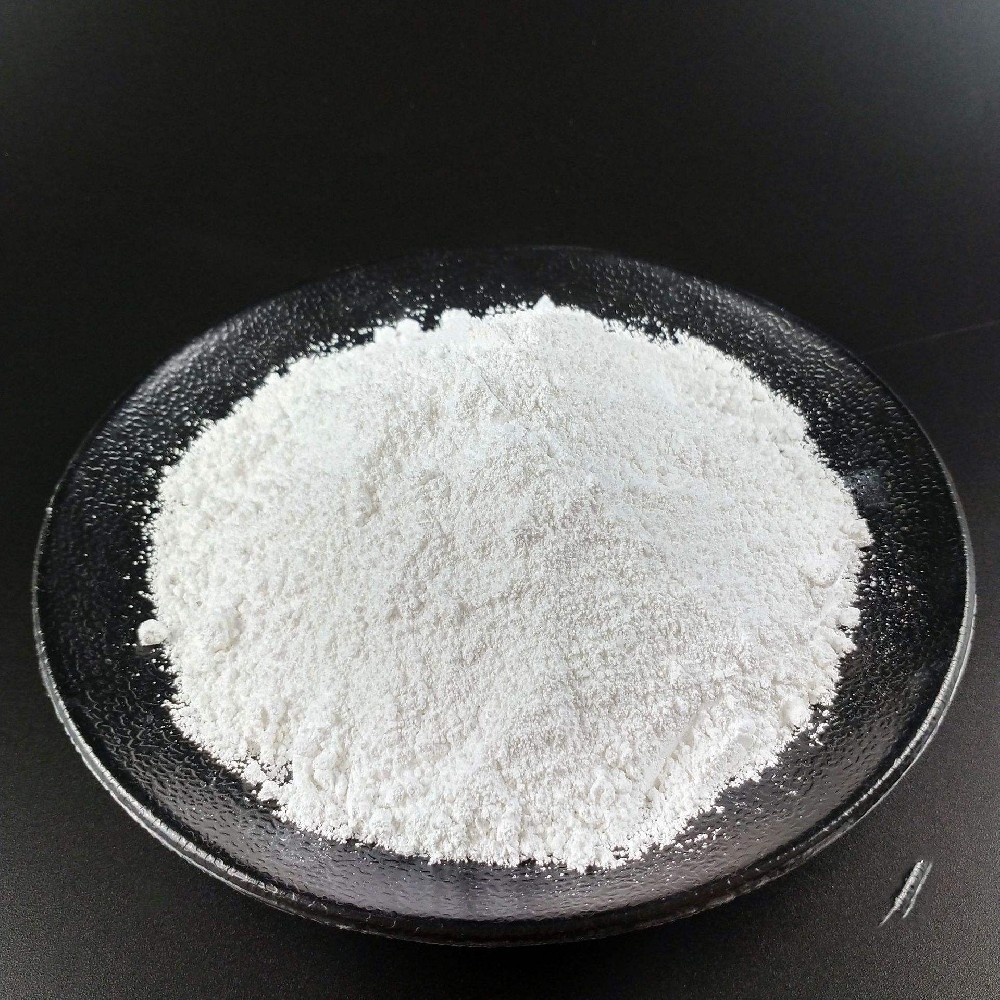

Calcium Carbonate

Polyvinyl chloride referred to as PVC, is a polymer formed by the polymerization of vinyl chloride monomer (VCM) in initiators such as peroxides, azo compounds or under the action of light and heat according to the mechanism of free radical polymerization. . Vinyl chloride homopolymers and vinyl chloride copolymers are collectively referred to as vinyl chloride resins.

PVC is a white powder with an amorphous structure with a small degree of branching. The glass transition temperature is 77 to 90 °C, and it begins to decompose at about 170 °C [1]. The stability to light and heat is poor. When exposed to sunlight, it will decompose to produce hydrogen chloride, which will further autocatalyze decomposition, causing discoloration and rapid decline in physical and mechanical properties. In practical applications, stabilizers must be added to improve the stability to heat and light.

PVC

The molecular weight of industrially produced PVC is generally in the range of 50,000 to 110,000. It has a large polydispersity. The molecular weight increases with the decrease of the polymerization temperature. At 160~180℃, it begins to transform into a viscous flow state; it has good mechanical properties, the tensile strength is about 60MPa, and the impact strength is 5~10kJ/m2; it has excellent dielectric properties.

PVC was once the largest general-purpose plastic in the world, and it is widely used. It is widely used in building materials, industrial products, daily necessities, floor leather, floor tiles, artificial leather, pipes, wires and cables, packaging films, bottles, foam materials, sealing materials, fibers, etc.

The oil absorption value is an indicator of the amount of resin absorbed by the filler.

In practical applications, calcium carbonate uses the oil absorption value to predict its demand for resin.

When the oil absorption value increases, the viscosity of the resin increases, which will change the rheological properties of the plastic.

If the oil absorption value is too small, the amount of calcium carbonate in the resin with a larger oil absorption value can be increased.

There are different expressions for the particle size and distribution of powder particles. Before there is no unified naming method, the plastic industry used to use the mesh number, that is, the particle size of the filler is generally expressed by the sieving rate that passes the equivalent mesh number.

The size of the particle size has a certain relationship with the oil absorption value. The particle size is small, the specific surface area is large, and the oil absorption value is also large. The viscosity of the material system for a given amount of use increases, so the amount added at this time should be small, such as light calcium carbonate.

The particle size distribution is wide, and the large and small particles are interspersed and embedded, so that the calcium carbonate particles are arranged relatively closely. At this time, only the minimum amount of resin can fill the gaps between the particles.

The specific surface area is the area of calcium carbonate per unit mass. Its size is directly related to the affinity between calcium carbonate and resin, calcium carbonate surface activation treatment and cost.

The size of the surface free energy of calcium carbonate particles is related to how well the calcium carbonate is dispersed in the resin. When the specific surface area is constant, the larger the surface free energy is, the easier the particles are to agglomerate, which affects the dispersion effect.

The density of the filler is related to the packing state of its particles. The volume of light calcium carbonate(also named Precipitated Calcium Carbonate) is larger than that of heavy calcium carbonate(also named Ground Calcium Carbonate), so the apparent density of light calcium carbonate is lower than that of heavy calcium carbonate. The particle size is not much different.

Due to the high hardness of calcium carbonate, filling calcium carbonate will improve the hardness and stiffness of plastic products, and significantly increase the elastic modulus of plastic products.

Due to the good thermal stability of calcium carbonate, the thermal expansion coefficient and shrinkage rate of the product can be reduced or decreased, and the warpage and curvature of the product can also be reduced. The deformation temperature also increases.

It has been found in many years of application that the dispersibility and fluidity of activated calcium carbonate are better than ordinary calcium carbonate.

The stability of activated calcium carbonate in use, the inherent strength, toughness and surface finish of the product are better than those of ordinary calcium carbonate, and are greatly improved, and at the same time, the physical and mechanical properties of the product can be greatly improved.

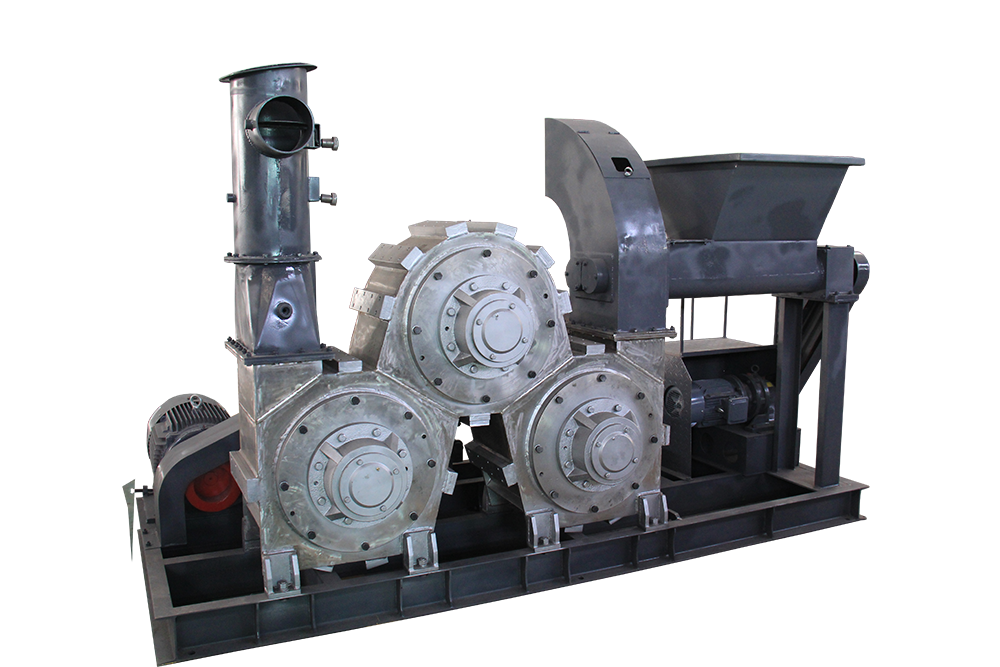

Industrially, calcium carbonate pulverizers include Raymond mills, vertical mills, ultra-fine mills, etc., and each model has many different models, which can meet the needs of different calcium carbonate processing and production.

1. European version coarse powder mill is used to produce calcium carbonate powder less than 8mm.

2. Raymond mill is used to produce fine calcium carbonate powder of 0.613-0.033mm.

3. Ultrafine grinding mill is used to produce 150-2500 mesh ultrafine calcium carbonate powder.

4. The ultra-fine vertical mill is used to produce 400-3000 mesh high-quality ultra-fine calcium carbonate powder.

Modified calcium carbonate is also called activated calcium carbonate. The so-called modified calcium carbonate means that the surface of heavy calcium carbonate or light calcium carbonate is prepared by activation treatment, which is not only hydrophobic but also activated.

Modified calcium carbonate is a versatile filler used in industries such as rubber, plastics, paper, coatings, paints, printing, cables, leather, medicine and food.

Its main features are that the particle size is less than 0.1um, the particle size is relatively uniform, the specific surface area is large, and the application performance is much better than that of ordinary calcium carbonate. It is widely used in PVC cable materials, synthetic leather, polyethylene films, foam plastic slippers and other products.

Plastic products filled with activated calcium carbonate can improve impact resistance. Activated calcium carbonate is used as a rubber supplement. When added to rubber products, its mechanical properties are significantly improved. For example, the tear strength can be more than doubled, and the number of flexures can be increased by 5-6 times. Therefore, activated calcium carbonate is both a filler for rubber. It is also a reinforcing agent for rubber.

Calcium carbonate powder surface coating machine is also named calcium carbonate powder modifier. It is to modify and dry the surface of calcium carbonate to improve the physical and chemical properties of its surface, enhance its compatibility with the matrix, that is, organic polymer or resin, etc. dispersibility to improve the mechanical strength and comprehensive properties of the material.

Calcium Carbonate Powder Surface Coating Machine

Shanghai CLIRIK Machinery Co.,Ltd. has been committed to the field of ultra-fine powder grinding machines for 20 years.

CLIRIK has a first-class manufacturing base with standardized and intelligent production lines.

CLIRIK's professional R&D, sales, installation and after-sales teams have provided door-to-door services to more than 100 countries and regions.

HGM grinding mill: 74-5 micron(200-2500 mesh); D97=5 micron

YGM Raymond mill: 613-33 micron(30-325 mesh); D90=30 micron

CLUM vertical roller mill: 20-5 micron(600-3000 mesh); D50=2 micron D97=4 micron

You can leave a message online or contact CLIRIK directly:

Email: sales@clirik.com

WhatsApp: +8613512155195/+8613917147829