Over View

Features

Applications

Technical Data

Introduction of Reversible Fine Crusher

New type of high efficiency and energy saving is the most advanced domestic reversible euro fine crusher, the fine crusher is mainly used in metallurgy, mining, chemical, cement, construction, refractory materials and ceramic industries as broken and fine

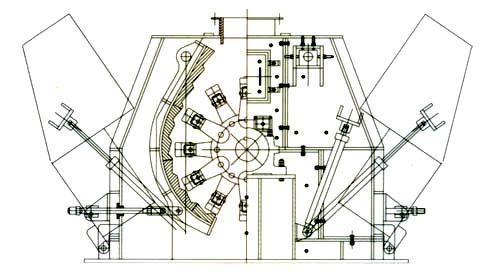

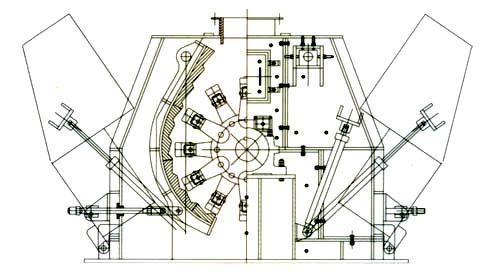

Working Principle of Reversible Fine Crusher

The machine adopts big rotor, small hammer head, low speed, the hammer head are arranged spiral, crackdown, high efficiency, the rotor side add uneven zigzag counterattack plate adjustment, material in high-speed spiral rotary hammer blow and fight back, under the function of the instantaneous crushing, grinding fineness high, cancel the old mill below perforated strainer, moisture applicability for the material, row material, material crushing fineness adjusted, and effectively overcome the old mill with high rotating speed and air pressure is big, thus effectively reduce the dust float in the sky .

1. Counterattack, hammer crusher, which is different from traditional structures, SHKX series adopts modular/double alloy hammer head, metal high utilization, saving the cost of production .

2. Hammer head are arranged spiral rotor, effectively improve the efficiency of combat, prevent material jam .

3. SHKX series euro fine crusher through the clearance between the back cavity lining plate and hammerhead and change hammer head is arranged to control the discharging granularity, so there is no install screen grate in discharge port .

4. Won't appear discharging mouth jam phenomenon, and less material in the crushing cavity retention time, reduce the part wear, long service life.

5. Crusher rotor bearing can include a thermal resistance temperature measurement device and vibration control device, can display the temperature field and the control host vibration overload protection, remote transmission to the total control room display, alarm (secondary instrument not worthy), making it easy for users to monitor equipment operation situation.

slags, construction materials, marble, and other more than 300 kinds of stone materials lumps or coarse powder making.

and this machine can be used in metallurgy, mining, chemical, cement, construction, refractory materials and ceramic industries

|

Model |

SHKX-950 |

SHKX-1200 |

SHKX-1600 |

SHKX-2000 |

|

Rotor Diameter (mm) |

950 |

1200 |

1600 |

2000 |

|

Rotor Length (mm) |

1200 |

1600 |

2000 |

2600 |

|

Max Feeding Size (mm) |

<80 |

<80 |

<80 |

<80 |

|

Diacharge Size (mm) |

<5 |

<5 |

<5 |

<5 |

|

Max Materials Moisture |

<15% |

<15% |

<15% |

<15% |

|

Capacity (t/h) |

50-100 |

100-200 |

200-380 |

380-550 |

|

Hammer Line Speed (m/s) |

56 |

62 |

62 |

70 |

|

Power (kw) |

90-110 |

250-315 |

560-630 |

800 |

|

Rotate Speed (r/min) |

990 |

980 |

740 |

740 |

|

Voltage (v) |

380 |

380 |

6000-10000 |

6000-10000 |

|

Hydraulic Couple (r/p) |

YOX600 |

YOX1000 |

YOX1150 |

YOX1250 |