For product information and pricing, Chat with sales agent:

or email us : sales@clirik.com

Click links below to see related products.

Plagioclase grinding mill machine is a kind of grinding equipment used to process plagioclase powder. The fineness of plagioclase powder that can be processed ranges from 30 mesh to 3000 mesh.

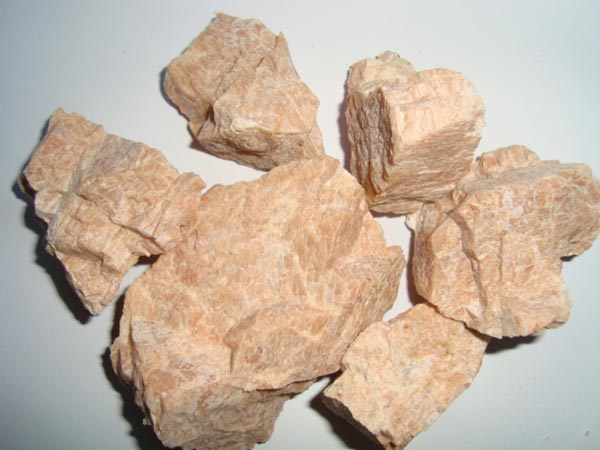

Plagioclase is a kind of feldspar. Plagioclase's Mohs hardness is between 6 and 6.5.

According to the content of end element, plagioclase is generally divided into six species and genera, including albite, feldspar, medium feldspar, elongate stone, plagioclase and anorthite.

Most varieties of plagioclase will produce fine and parallel stripes on the surface, and some will have blue or green halos, which is caused by their bicrystal structure.

Plagioclase is widely distributed in magmatic rocks, metamorphic rocks and sedimentary clastic rocks. It is the main raw material of ceramic industry and glass industry

The melting point of plagioclase is between 1100-1300 ℃, with good chemical stability. It is helpful for melting when CO melting with quartz and aluminosilicate.

It is often used as a flux for making glass and ceramic glaze, and can reduce the firing temperature.

In the enamel raw material industry, plagioclase and other mineral raw materials can be used to prepare enamel.

In addition, plagioclase can also be used in abrasive industry.

Plagioclase powder has many uses, so what machines can process plagioclase powder? Below we will mainly introduce five kinds of machines that can process plagioclase powder.

The material below 20mm is sent to the feeding hopper by the bucket elevator. The feeding hopper sends the material into the grinding chamber and falls on the grinding ring. The continuously rotating grinding ring gives the material a centrifugal force to move it to the outer circle. , into the grinding range of the grinding roller.

After grinding, the material falls from the edge of the grinding ring, is blown up by the hot air sent by the blower, and is separated by the cyclone separator. The qualified material leaves the grinding chamber, and the unqualified material falls back into the grinding ring.

The high-pressure micro powder mill is an advanced version of the Raymond mill, which grinds materials by the extrusion force generated by the opposite rotation of two horizontally installed extrusion rollers. After the material enters the grinding chamber, the closed material layer moves downward under the action of gravity. During the movement, it is pressed into a cake by the pressure of the extrusion roller, and the cake contains a large amount of fine powder.

The feed particle size of the micro powder grinding mill is below 15-25mm, the finished product particle size is 0.125-0.010mm, and the production capacity is 0.2-12 tons per shift.

The three-ring/four-ring ultra-fine grinding mill grinds the material repeatedly through multiple loops to obtain ultra-fine powder efficiently.

The main part of the ultrafine grinding mill is composed of the main engine, the reducer, the analyzer, the fan, the bypass powder collector, the maintenance platform and the electric control cabinet. The auxiliary machine part consists of jaw crusher, bucket elevator, electromagnetic vibrating feeder, storage bin and so on.

The material enters the equipment, is thrown to the edge of the turntable, falls into the grinding chamber, and undergoes multiple grinding to become powder. The fan pulls the ground powder away, which is controlled by the powder concentrator. The powder that does not meet the requirements is returned to the machine cavity and ground again to become finer. The powder that can pass through the powder separator is the finished product, and the pulse dust collector separates the powder from the air to achieve the purpose of collection. The production process operates under negative pressure, and there is no dust spillage.

The fineness of the finished product of the ultrafine pulverizer is between 150-3000 mesh, and the output can reach up to 50 tons/hour.

Vertical roller mill is a grinding equipment that integrates crushing, drying, grinding, grading and conveying. The grinding principle is similar to that of Raymond mill. The difference is that it can blow hot air into the grinding chamber, saving a The cost of the dryer.

The fineness of the finished product of the vertical roller mill is between 0.17-0.033mm, the model is from small to large, and the processing capacity can be from 10-40 tons per hour to 90-320 tons per hour.

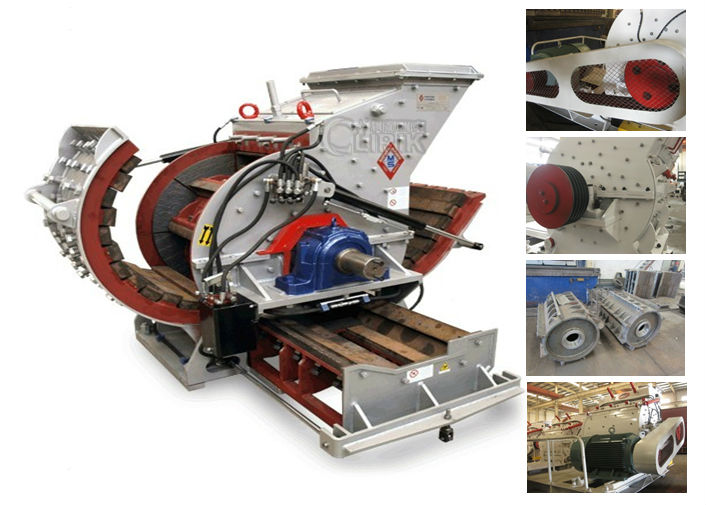

The European-style coarse powder grinding mill can crush all kinds of ores with a compressive strength of not more than 320MPa. The structure of the coarse grinding mill mainly includes a casing, a rotor, a hammer head, a grate bar, etc. The materials are crushed by the impact force brought by the high-speed rotating hammer head. The humidity of the crushed material should not exceed 5%.

The feeding particle size of the European-style coarse powder mill is below 100mm, and the output particle size is 0-3mm, which can process 35-132 tons of materials per hour.

To sum up, how much the output size of plagioclase powder can reach depends on what kind of mill you use.

Shanghai CLIRIK Machinery Co.,Ltd. has been committed to the field of ultra-fine powder grinding machines for 20 years.

CLIRIK has a first-class manufacturing base with standardized and intelligent production lines.

CLIRIK's professional R&D, sales, installation and after-sales teams have provided door-to-door services to more than 100 countries and regions.

HGM grinding mill: 74-5 micron(200-2500 mesh); D97=5 micron

YGM Raymond mill: 613-33 micron(30-325 mesh); D90=30 micron

CLUM vertical roller mill: 20-5 micron(600-3000 mesh); D50=2 micron D97=4 micron

You can leave a message online or contact CLIRIK directly:

Email: sales@clirik.com

WhatsApp: +8613512155195/+8613917147829