For product information and pricing, Chat with sales agent:

or email us : sales@clirik.com

Click links below to see related products.

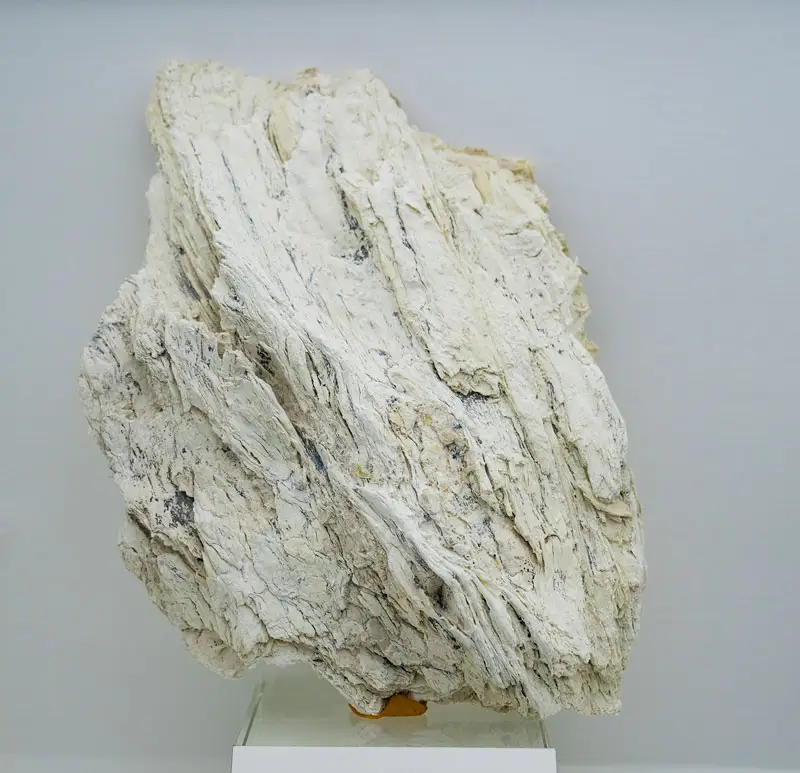

Sepiolite is a naturally occurring clay mineral of sedimentary origin. Lightweight porous clay with a large specific surface area that does not swell. Chemically, sepiolite is a hydraulic magnesium silicate, and its individual particles are in the form of pins.

Sepiolite

Sepiolite can be applied to air purification, water purification filter elements, architectural coatings, sepiolite handicrafts, etc; In industry, we can produce feed mold remover, oil drilling flame retardant, and chemical industry applications.

The higher the purity of sepiolite, the better its physical and chemical properties and process properties, the wider the range of use, and the further improvement of its application value. At present, the processing of sepiolite is mainly divided into two aspects: basic processing and deep processing.

Ball mill milling and beneficiation and purification are the main methods of basic processing of sepiolite.

For coarse-grained sepiolite, ball milling can be used to obtain sepiolite with a particle size range of 0.2 to 0.6 mm.

Ball Mill For Sepiolite

For sepiolite from different origins and uses, different types of ball mills can be used for basic processing.

Ball mill milling is not only beneficial for beneficiation and purification, but also different components can be added to meet the preparation requirements of various materials.

The application prospect of sepiolite depends on the degree of deep processing.

The deep processing of sepiolite mainly includes ultra-fine processing, activation, surface modification and other methods. Among them, ultra-fine processing is usually processed by ultrafine mill and Raymond mill according to the different requirements for product fineness.

Ultrafine Grinding Mill

Raymond Mill

At present, the methods of sepiolite modification mainly include acid modification, ion exchange modification, roasting treatment modification and organic modification.

Sepiolite beneficiation and purification technologies are mainly divided into two types: dry method and wet method. Among them, wet beneficiation and purification technology is widely used. The wet beneficiation and purification technology is mainly based on physical methods such as depolymerization and dispersion, gravity, centrifugal force, and selective flocculation separation, supplemented by comprehensive beneficiation and purification processes such as flotation.

Natural sepiolite contains a lot of impurities, resulting in a small specific surface area and narrow pores.

When it is used as a composite material in other fields, it needs to be purified and modified.

The purification and modification methods of sepiolite mainly include heat treatment, acid modification, surfactant modification, coupling agent modification, and polymer coating modification.

There are two main methods of sepiolite heat treatment: hydrothermal treatment and roasting.

Hydrothermal treatment is a method of placing the mixture of sepiolite and water in a reaction kettle and stirring for a period of time at a certain temperature to obtain ultra-fine sepiolite;

Roasting method means that some organic substances and carbonate substances contained in sepiolite can be sintered or phase-transformed under high-temperature conditions through a series of heating.

In the process, the adsorbed water, zeolite water, crystal water and structural water in the sepiolite are successively removed, so that the structure changes accordingly.

The hydrothermal treatment of sepiolite can not only solve the phenomenon of fiber monomer aggregation but also increase the specific surface area and acid activation speed.

But the appropriate stirring temperature, stirring speed, and stirring time should be selected during the treatment process.

The specific surface area of the piolite will be destroyed at the same time.

Most sepiolites have shortcomings such as strong interlayer or inter-fiber adhesion, and high fiber strength after swelling.

Stone and water twenty times the weight of sepiolite were added to the reactor, and the water was heated in the range of 393-493K for a period of time.

The crystal structure of sepiolite did not change significantly, but the specific surface area of sepiolite showed an obvious increasing trend with the increase in temperature.

In addition, the acid activation rate of sepiolite after hydrothermal treatment accelerated and acid activated sepiolite The adsorption decolorization rate also increased.

Acid-modified sepiolite is one of the main methods for the purification of sepiolite, which is obtained by mixing a series of strong acids with sepiolite, stirring for a period of time and drying.

Surfactants are a class of amphiphilic substances that can change the interface state of a solution system, usually with a hydrophilic polar group at one end and a lipophilic non-polar group at the other end.

The active agents commonly used in the surface modification of sepiolite include sulfonate anionic surfactants such as sodium dodecylbenzene sulfonate and quaternary ammonium salt cationic surfactants such as cetyltrimethylammonium bromide.

Surfactant modification can not only reduce the surface energy, change the polarity of sepiolite, make sepiolite change from hydrophilic to lipophilic, but also increase the layered units of silicon-oxygen tetrahedron and magnesium-oxygen octahedron.

The resulting interlayer spacing makes it possible for polymer chains or monomers to enter the interlayer to further improve their properties.

The molecule of the coupling agent contains two groups with different chemical properties of inorganic and organic compounds, which are used to improve the interface between inorganic and organic substances, thereby greatly improving the performance of composite materials.

Silane coupling agent is commonly used in the study of coupling agent modified sepiolite.

The silane coupling agent is composed of a siloxy group reactive with inorganic substances and an organic functional group reactive or compatible with organic substances.

During the modification process, the silanols generated by the hydrolysis of the organosilane react with the —OH on the surface of the sepiolite, so that the organosilane is grafted to the surface of the sepiolite. Not only can improve the shrinkage performance of its surface, but also can reduce its surface energy.

The inorganic-organic composite material can be obtained by dispersing or dissolving the polymer monomer or polymer in the solvent as the matrix of the polymer composite material, and adding the inorganic filler dispersed phase to act for a period of time under certain conditions.

The inorganic fillers that have been studied more at present are mainly a class of natural layered silicate clay minerals, such as diatomite, montmorillonite, and sepiolite.

Although the coating of polymer and sepiolite can be directly achieved under certain technical conditions, the organically treated sepiolite can improve its affinity with the polymer and improve the performance of the polymer.

Shanghai CLIRIK Machinery Co.,Ltd. has been committed to the field of ultra-fine powder grinding machines for 20 years.

CLIRIK has a first-class manufacturing base with standardized and intelligent production lines.

CLIRIK's professional R&D, sales, installation and after-sales teams have provided door-to-door services to more than 100 countries and regions.

HGM grinding mill: 74-5 micron(200-2500 mesh); D97=5 micron

YGM Raymond mill: 613-33 micron(30-325 mesh); D90=30 micron

CLUM vertical roller mill: 20-5 micron(600-3000 mesh); D50=2 micron D97=4 micron

You can leave a message online or contact CLIRIK directly:

Email: sales@clirik.com

WhatsApp: +8613512155195/+8613917147829