For product information and pricing, Chat with sales agent:

or email us : sales@clirik.com

Click links below to see related products.

The HGM Ultrafine Grinding Mill is suitable for ultrafine grinding of non-flammable, non-explosive, and brittle materials with medium to low hardness (Mohs hardness ≤ 6).It is an ideal equipment for processing attapulgite fine and ultrafine powder.

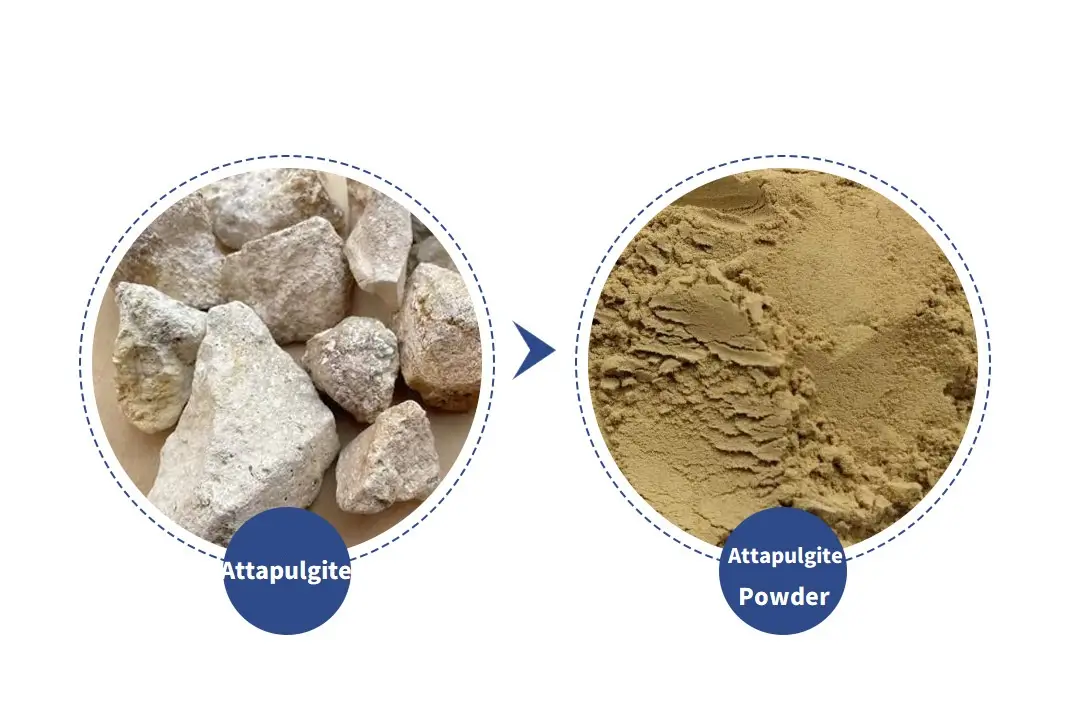

Ore Drying: After mining, the attapulgite ore is dried on-site to remove excess moisture and facilitate subsequent processing.

Preliminary Crushing: The air-dried ore is crushed to a particle size suitable for grinding in the grinding mill.

Grinding: The crushed attapulgite is fed into the HGM Ultrafine Grinding Mill, where the relative motion of the grinding rollers and grinding rings grinds the material. The final powder particle size can be adjusted between 325 and 3000 mesh.

Classification: The ground material is classified by a classifier. Material that does not meet the required fineness is returned to the grinding mill for re-grinding, while material that meets the required fineness is transferred to the next step.

Collection: Attapulgite powder that meets the required fineness is collected by a collection device. Drying: If necessary, the collected powder can be further dried.

Equipment Selection: Select the appropriate HGM grinding mill model based on your production needs to ensure the equipment's output and fineness meet your processing requirements.

Maintenance: Regularly maintain the equipment, inspect wear on wearing parts such as the grinding rollers and grinding rings, and replace them promptly to ensure normal operation.

Environmental Protection: While the HGM ultrafine grinding mill is environmentally friendly and clean, proper dust collection and disposal are still required to avoid environmental pollution.

High Output: For equivalent finished product fineness and motor power, the HGM ultrafine grinding mill achieves 40%-45% higher output than airflow mills and stirred mills.

Low Energy Consumption: Compared to traditional grinding equipment, the HGM ultrafine grinding mill consumes less energy when processing attapulgite, effectively reducing production costs.

Wear-Resistant Materials: The grinding rollers and grinding rings are forged from special wear-resistant materials, significantly enhancing durability. When processing materials like attapulgite, the service life of wearing parts is 2-3 times longer than that of conventional grinding mills, typically exceeding one year. When processing calcium carbonate and calcite, the service life can reach 2-5 years.

Structural Advantages: The grinding chamber contains no rolling bearings or screws, eliminating the risk of bearing and seal wear or loose screws damaging the machine, resulting in safer and more reliable operation.

Adjustable Fineness: The finished product fineness can be adjusted between 325-3000 mesh, achieving a D97 ≤ 5μm in one pass, meeting the fineness requirements of attapulgite powder in various applications.

Dust Removal and Noise Reduction: Utilizing a high-efficiency pulse dust collector, the entire equipment operates without dust pollution. A muffler and soundproofing chamber further reduce noise levels, ensuring compliance with national environmental standards.

Processed attapulgite powder has a variety of applications. The following are some of its main areas of application:

Wastewater Treatment: Due to its excellent adsorption properties, attapulgite powder can be used as an adsorbent to remove heavy metal ions, organic matter, and other harmful substances from water. For example, when treating chromium-containing wastewater, adding activated attapulgite clay can achieve a chromium removal rate of 99.75%.

Home Water Purifiers: It can be used in home water purifiers to effectively remove impurities and odors from water.

Decolorizer: It is used for decolorizing and purifying vegetable oils, animal oils, glucose, and other products. For example, in vegetable oil refining, attapulgite powder can reduce the acid value of the oil, preventing it from discoloring during long-term storage.

Food Additive: It can be used as a food additive for sugar juice purification and decolorization.

Molecular Sieve Support: Attapulgite powder can be used as a molecular sieve support in catalytic reactions. Adsorbent: Used in chemical production to absorb harmful gases and impurities from liquids.

New Wall Materials: Can be used to manufacture new wall materials, such as binders for mineral wool sound-absorbing panels.

Concrete Additive: Serves as a plasticizer and additive in concrete, improving its performance.

Soil Conditioner: Can be used to improve soil structure, enhance water retention, and improve fertility.

Feed Additive: Serves as a carrier, binder, and adsorbent in animal feed, improving feed quality.

Drug Carrier: Can be used as a filler, carrier, and additive in pharmaceuticals.

Medical Adsorbent: Used to absorb and remove harmful substances from the body.

Air Purification: Can be used to purify air and remove harmful gases and odors.

Radioactive Waste Treatment: Attapulgite powder has excellent adsorption properties for radioactive substances and can be used in radioactive waste treatment.

Cosmetics: In cosmetics, attapulgite powder is used in facial masks and skin care products due to its excellent absorbency and tactile feel.

Textile Printing and Dyeing: It can be used for filling, bleaching, and antistatic coating of textiles.

Due to its unique physical and chemical properties, attapulgite powder has a wide range of applications in various fields, and its scope of application continues to expand with technological advancements.