For product information and pricing, Chat with sales agent:

or email us : sales@clirik.com

Click links below to see related products.

The manufacturing process equipment for producing tonalite products, such as slabs, tiles, or crushed stone, typically involves several key pieces of machinery and equipment.

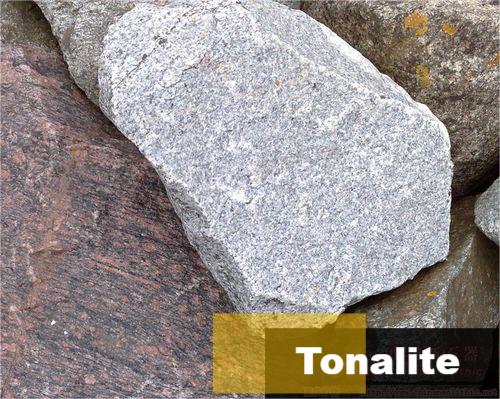

Tonalite is a type of igneous rock that is part of the plutonic rock family. It is primarily composed of plagioclase feldspar, quartz, and sometimes small amounts of hornblende, biotite, or other minerals. Tonalite is known for its relatively coarse-grained texture and typically appears light to medium gray in color.

Geologically, tonalite forms deep within the Earth's crust as molten magma cools and solidifies. It is often associated with granite and other similar igneous rocks. Tonalite can be found in various geological settings, including mountain ranges and areas with a history of volcanic activity.

In addition to its geological significance, tonalite is sometimes used as a dimension stone in construction and as a decorative material in architectural and landscaping applications due to its durability and attractive appearance.

Tonalite, as an igneous rock, has several practical uses and applications:

Construction material: Tonalite is durable and can withstand significant pressure and wear, making it suitable for a variety of construction purposes, such as building facades, countertops, and flooring.

Dimension stone: Tonalite is often quarried and cut into slabs for use as dimension stone in architectural and decorative applications. It can be polished to a high shine, making it a desirable choice for monuments, sculptures, and other ornamental features.

Paving and landscaping: Tonalite can be used in outdoor applications such as paving stones, retaining walls, and decorative landscaping elements due to its resistance to weathering and its pleasing appearance.

Gravestones and memorials: Tonalite is sometimes used for gravestones and memorial markers because of its durability and the ease with which it can be engraved.

Kitchen countertops and vanities: Tonalite's resistance to scratching and staining makes it a popular choice for kitchen countertops and bathroom vanities.

Crushed stone and aggregates: Tonalite can be crushed and used as an aggregate material in construction, particularly in the production of concrete and asphalt.

Ballast: It is used as a ballast material for railways and as a stabilizing material for road construction.

Riprap: Tonalite can be used as riprap, large stones or concrete blocks placed along shorelines, embankments, and other erosion-prone areas to reduce erosion and protect against flooding.

Industrial applications: In some cases, tonalite may be used in industrial processes, such as in the manufacture of ceramics and refractory materials.

The specific uses of tonalite can vary depending on its appearance, availability, and local geological conditions. It is valued for its strength and resistance to wear, which makes it a versatile and practical choice for various construction and decorative applications.

The processing of tonalite involves various steps depending on its intended use. Here's a general overview of the process for extracting, cutting, and finishing tonalite for various applications:

Quarrying: Tonalite is first extracted from quarries or mines using heavy machinery and drilling equipment. The tonalite blocks are cut from the earth in large pieces, often with the use of explosives.

Cutting and shaping: Once the tonalite blocks are extracted, they are transported to a processing facility where they are cut and shaped into the desired dimensions and forms. This can be done using diamond wire saws, gang saws, or other cutting equipment. The tonalite is typically cut into slabs, tiles, or blocks, depending on the intended application.

Polishing: For decorative and architectural purposes, tonalite can be polished to achieve a smooth and glossy finish. This process involves using abrasive materials and machinery to grind and polish the surface to the desired level of smoothness and shine.

Surface finishes: Tonalite can be finished in various ways depending on its application. Common finishes include honed (a matte finish), brushed (textured surface), flamed (rough, textured surface achieved through high-temperature treatment), and more.

Quality control: Throughout the processing stages, quality control measures are implemented to ensure that the tonalite meets the required specifications, including size, thickness, and surface finish.

Transportation and installation: Processed tonalite is then packaged and transported to construction sites, manufacturing facilities, or distribution centers. It is installed according to the project's requirements, whether it's for building facades, countertops, flooring, or other applications.

Maintenance: Tonalite surfaces, especially those used in high-traffic or outdoor areas, may require periodic maintenance, including sealing and cleaning, to preserve their appearance and durability.

It's important to note that the specific processing steps and techniques may vary depending on the equipment and technology available at the processing facility and the intended use of the tonalite. Proper safety measures and environmental regulations should also be followed during the extraction and processing of tonalite.

Tonalite powder is not a commonly recognized or used material in various industries or applications, as it is typically found and used in solid form, such as blocks, slabs, or crushed stone. However, if you are interested in exploring potential uses for tonalite in powdered form, you could consider the following possibilities:

Soil Amendment: Powdered tonalite, when finely ground, may be used as a soil amendment to improve soil structure and mineral content. It can provide essential nutrients like potassium, calcium, and magnesium to the soil, helping to enhance plant growth.

Concrete and Mortar Additive: Fine tonalite powder could be used as an additive in concrete and mortar mixes to improve their strength and durability. It can act as a mineral filler and enhance the properties of construction materials.

Fertilizer Component: Tonalite powder might be incorporated into specialized fertilizers as a source of essential plant nutrients. Its mineral content can contribute to soil fertility.

Industrial Applications: Tonalite powder might have niche applications in certain industrial processes where the specific properties of the minerals in tonalite are desirable. This could include uses in ceramics, refractories, or as a flux in metallurgical processes.

Art and Craft Supplies: Tonalite powder could potentially be used in art and craft projects as a natural pigment or texture medium.

Scientific Research: Fine powders of tonalite might be used in geological or materials science research for various experiments and analysis.

It's important to note that the practicality and suitability of tonalite powder for these uses would depend on factors like the mineral composition of the tonalite, its particle size, and any specific characteristics it possesses. Before using tonalite powder for any of these applications, thorough testing and analysis should be conducted to determine its compatibility and effectiveness for the intended purpose. Additionally, safety and environmental regulations should be followed when handling and using mineral powders.

Processing tonalite into powder involves several steps, including extraction, crushing, grinding, and sizing. Here's a general overview of how tonalite can be processed into powder:

Quarrying and Extraction: Tonalite is first extracted from quarries or mines using heavy machinery and drilling equipment. The tonalite blocks are cut from the earth in large pieces, typically with the use of explosives.

Crushing: The extracted tonalite is transported to a primary crushing facility, where it is initially broken down into smaller pieces using jaw crushers or impact crushers. The primary crusher reduces the tonalite into chunks that are more manageable in size.

Secondary Crushing and Grinding: The larger chunks from the primary crusher are further crushed into smaller fragments using secondary crushers, such as cone crushers or gyratory crushers. After this, the material can be further ground down into smaller particles through grinding processes. This can be done with ball mills, Raymond mills, ultrafine mills, or other grinding equipment to achieve the desired particle size.

Sizing and Classification: Once the tonalite has been ground down into fine particles, it may go through a classification process to ensure that the powder has a consistent particle size. This can be achieved using screens or classifiers to separate the powder into different size fractions.

Packaging and Storage: The tonalite powder is then packaged into appropriate containers, which can vary depending on the specific application and market. It is essential to store the powder in a controlled environment to prevent contamination and maintain its quality.

Quality Control: Throughout the processing stages, quality control measures are essential to ensure that the tonalite powder meets the required specifications, including particle size, purity, and other relevant parameters.

Safety and Environmental Considerations: Ensure that safety measures and environmental regulations are followed during the extraction and processing of tonalite. Dust control and other safety precautions should be in place to protect workers and the environment.

The specific processing steps and techniques may vary depending on the equipment and technology available at the processing facility and the intended use of the tonalite powder. It's also important to consider the composition of the tonalite and the desired particle size for the end application, as these factors can influence the processing methods used.

The manufacturing process equipment for producing tonalite products, such as slabs, tiles, or crushed stone, typically involves several key pieces of machinery and equipment. These are used for tasks like cutting, shaping, and finishing the tonalite. Here are some of the common equipment used in the manufacturing process of tonalite products:

Quarry Equipment: This includes heavy machinery and equipment used in the extraction of tonalite from quarries or mines. Equipment may include bulldozers, excavators, front-end loaders, and drilling rigs for quarrying and mining operations.

Primary Crusher: In the initial stages of processing, a primary crusher is used to break down large tonalite blocks into smaller, more manageable pieces. Common types of primary crushers include jaw crushers and impact crushers.

Secondary Crusher: After the initial crushing, secondary crushers, such as cone crushers or gyratory crushers, may be used to further reduce the size of the tonalite fragments.

Grinding Equipment: To create tonalite powder or to achieve a specific particle size, grinding equipment like ball mills, rod mills, or hammer mills may be used. These machines grind the tonalite into fine particles.

Cutting and Shaping Equipment: For cutting tonalite into slabs, tiles, or blocks, equipment like diamond wire saws, gang saws, and bridge saws are commonly used. These machines precision-cut the tonalite to the desired dimensions and forms.

Polishing Machines: If the tonalite is intended for decorative and architectural applications, polishing machines are used to achieve a smooth and glossy finish. These machines use abrasive materials to polish the surface of the tonalite.

Calibrating and Profiling Machines: These machines ensure that the tonalite products have consistent thickness and dimensions. They are particularly important for products like countertops and flooring tiles.

Surface Finish Machines: For achieving specific surface finishes like honed, brushed, flamed, or textured, specialized equipment may be used to create the desired texture or appearance.

Edge Profiling Equipment: This equipment is used to shape the edges of tonalite products, especially for countertops and similar applications. It can add decorative or functional profiles to the edges.

Sizing and Classification Equipment: In cases where tonalite powder or smaller fragments are produced, sizing and classification equipment, such as screens and classifiers, are used to separate the material into different size fractions.

Dust Control and Environmental Equipment: To maintain a safe and clean working environment and comply with environmental regulations, dust control systems and other environmental control equipment are often utilized in tonalite manufacturing facilities.

The specific equipment used can vary based on the type of tonalite product being manufactured, the scale of production, and the technology available at the processing facility. Safety measures and quality control procedures should be followed throughout the manufacturing process to ensure the quality and safety of the tonalite products.

Shanghai CLIRIK Machinery Co.,Ltd. has been committed to the field of ultra-fine powder grinding machines for 20 years.

CLIRIK has a first-class manufacturing base with standardized and intelligent production lines.

CLIRIK's professional R&D, sales, installation and after-sales teams have provided door-to-door services to more than 100 countries and regions.

HGM grinding mill: 74-5 micron(200-2500 mesh); D97=5 micron

YGM Raymond mill: 613-33 micron(30-325 mesh); D90=30 micron

CLUM vertical roller mill: 20-5 micron(600-3000 mesh); D50=2 micron D97=4 micron

You can leave a message online or contact CLIRIK directly:

Email: sales@clirik.com

WhatsApp: +8613512155195/+8613917147829