For product information and pricing, Chat with sales agent:

or email us : sales@clirik.com

Click links below to see related products.

Serpentine is a general term for hydrous magnesium-rich silicate minerals, such as antigorite, lizardite, and chrysotile. Their color is generally green, but also light gray, white or yellow.

Serpentine

The structure of serpentine often has curls, like fibers. Such serpentine is often used as asbestos.

Both massive and fibrous serpentine are lustrous, massive like wax and fibrous like silk. People use serpentine as a building material, and some can be used as refractory materials, and those with good colors can also be made into decorations or handicrafts.

In addition, serpentine can also be used to make fertilizers.

Serpentine minerals have broad application prospects because of their heat resistance, corrosion resistance, wear resistance, heat insulation, sound insulation, and good process characteristics. At present, they are mainly used in the manufacture of fertilizers, refractory materials, pharmaceutical industry, and carving materials.

Due to its heat resistance, corrosion resistance, wear resistance, heat insulation, sound insulation, good process characteristics and associated beneficial components, serpentine minerals have broad application prospects and are mainly used in the following aspects:

1. Manufacture of fertilizers. Serpentine is calcined together with apatite or phosphorite to make calcium magnesium phosphate fertilizer. If serpentine fine powder is applied alone, it also has a certain fertilizer effect. Especially for corn, potatoes, beans and root and tuber crops, the effect is better.

2. As a refractory material. For example, Tangshan Iron and Steel Plant uses serpentine to make serpentine coke oven bricks, and steel factories such as Chongqing and Taiyuan use serpentine to make forsterite bricks. As an alkaline refractory material, the effect is very good.

3. The serpentine used in the pharmaceutical industry can be used as a raw material for making Epsom salt.

4. Extraction of magnesium Metal magnesium can be extracted if the magnesium content is high. Cobalt and nickel can also be extracted from serpentinite with high cobalt and nickel content.

5. Extraction of fibrous amorphous silicon The amorphous silicon extracted from serpentine reacts with carbon at high temperature to produce silicon whiskers, crystal powder and crystals.

6. The engraving material Serpentinite, which is bright, transparent, translucent, dense and hard, can be used as raw material for jade handicrafts. There are more than ten kinds of serpentine jade in China, such as Xiuyan jade in Liaoning, which is well-known at home and abroad.

7. Auxiliary raw materials for the production of cast stone or rock wool If MgO is insufficient in cast stone or rock wool ingredients, serpentine can be used as auxiliary raw materials to increase the content of Mg0 and relatively reduce the content of Al2O3 and CaO.

Serpentine mines are generally mined from rich ore bodies. The raw ore is crushed and screened, and it can be sold after reaching a certain size requirement.

In order to explore the separation way of serpentine and its associated useful minerals, the flotation characteristics of serpentine were also studied. The results show that both sodium oleate and dodecylamine hydrochloride have good collection properties for serpentine. It is speculated that the Mg particles on the surface of the serpentine are the active sites for the adsorption of oleic acid radicals, and when the cation collector is used for flotation with dodecylamine salt, the amine is adsorbed on the surface of the serpentine in a molecular state. Water glass has a strong inhibitory effect on serpentine flotation.

The material below 20mm is sent to the feeding hopper by the bucket elevator. The feeding hopper sends the material into the grinding chamber and falls on the grinding ring. The continuously rotating grinding ring gives the material a centrifugal force to move it to the outer circle. , into the grinding range of the grinding roller.

After grinding, the material falls from the edge of the grinding ring, is blown up by the hot air sent by the blower, and is separated by the cyclone separator. The qualified material leaves the grinding chamber, and the unqualified material falls back into the grinding ring.

The high-pressure micro powder mill is an advanced version of the Raymond mill, which grinds materials by the extrusion force generated by the opposite rotation of two horizontally installed extrusion rollers. After the material enters the grinding chamber, the closed material layer moves downward under the action of gravity. During the movement, it is pressed into a cake by the pressure of the extrusion roller, and the cake contains a large amount of fine powder.

The feed particle size of the micro powder grinding mill is below 15-25mm, the finished product particle size is 0.125-0.010mm, and the production capacity is 0.2-12 tons per shift.

The three-ring/four-ring ultra-fine grinding mill grinds the material repeatedly through multiple loops to obtain ultra-fine powder efficiently.

The main part of the ultrafine grinding mill is composed of the main engine, the reducer, the analyzer, the fan, the bypass powder collector, the maintenance platform and the electric control cabinet. The auxiliary machine part consists of jaw crusher, bucket elevator, electromagnetic vibrating feeder, storage bin and so on.

The material enters the equipment, is thrown to the edge of the turntable, falls into the grinding chamber, and undergoes multiple grinding to become powder. The fan pulls the ground powder away, which is controlled by the powder concentrator. The powder that does not meet the requirements is returned to the machine cavity and ground again to become finer. The powder that can pass through the powder separator is the finished product, and the pulse dust collector separates the powder from the air to achieve the purpose of collection. The production process operates under negative pressure, and there is no dust spillage.

The fineness of the finished product of the ultrafine pulverizer is between 150-3000 mesh, and the output can reach up to 50 tons/hour.

Vertical roller mill is a grinding equipment that integrates crushing, drying, grinding, grading and conveying. The grinding principle is similar to that of Raymond mill. The difference is that it can blow hot air into the grinding chamber, saving a The cost of the dryer.

The fineness of the finished product of the vertical roller mill is between 0.17-0.033mm, the model is from small to large, and the processing capacity can be from 10-40 tons per hour to 90-320 tons per hour.

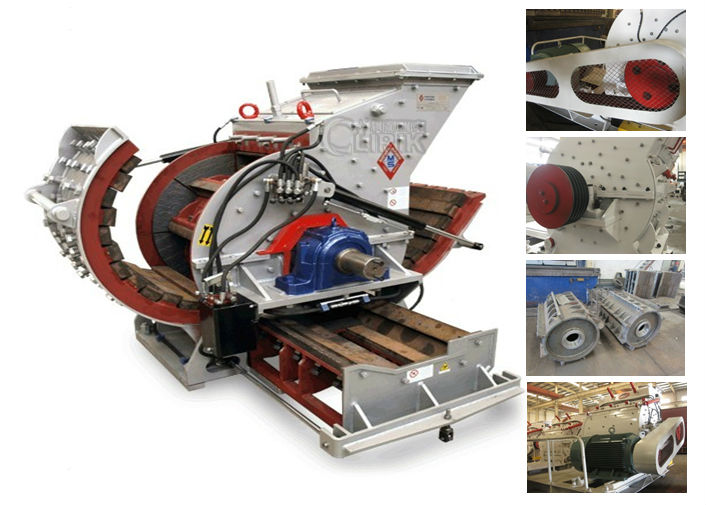

The European-style coarse powder grinding mill can crush all kinds of ores with a compressive strength of not more than 320MPa. The structure of the coarse grinding mill mainly includes a casing, a rotor, a hammer head, a grate bar, etc. The materials are crushed by the impact force brought by the high-speed rotating hammer head. The humidity of the crushed material should not exceed 5%.

The feeding particle size of the European-style coarse powder mill is below 100mm, and the output particle size is 0-3mm, which can process 35-132 tons of materials per hour.

To sum up, how much the output size of plagioclase powder can reach depends on what kind of mill you use.

Shanghai CLIRIK Machinery Co.,Ltd. has been committed to the field of ultra-fine powder grinding machines for 20 years.

CLIRIK has a first-class manufacturing base with standardized and intelligent production lines.

CLIRIK's professional R&D, sales, installation and after-sales teams have provided door-to-door services to more than 100 countries and regions.

HGM grinding mill: 74-5 micron(200-2500 mesh); D97=5 micron

YGM Raymond mill: 613-33 micron(30-325 mesh); D90=30 micron

CLUM vertical roller mill: 20-5 micron(600-3000 mesh); D50=2 micron D97=4 micron

You can leave a message online or contact CLIRIK directly:

Email: sales@clirik.com

WhatsApp: +8613512155195/+8613917147829