For product information and pricing, Chat with sales agent:

or email us : sales@clirik.com

Click links below to see related products.

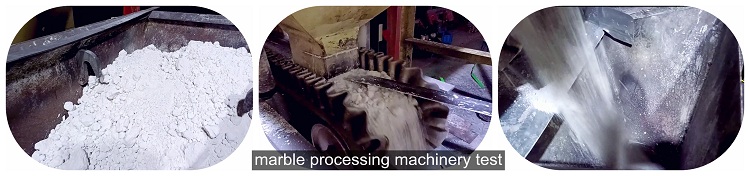

As the pictures shown, in last week there was a client send us about 200 kg marble for our HGM grinding mill machinery testing.

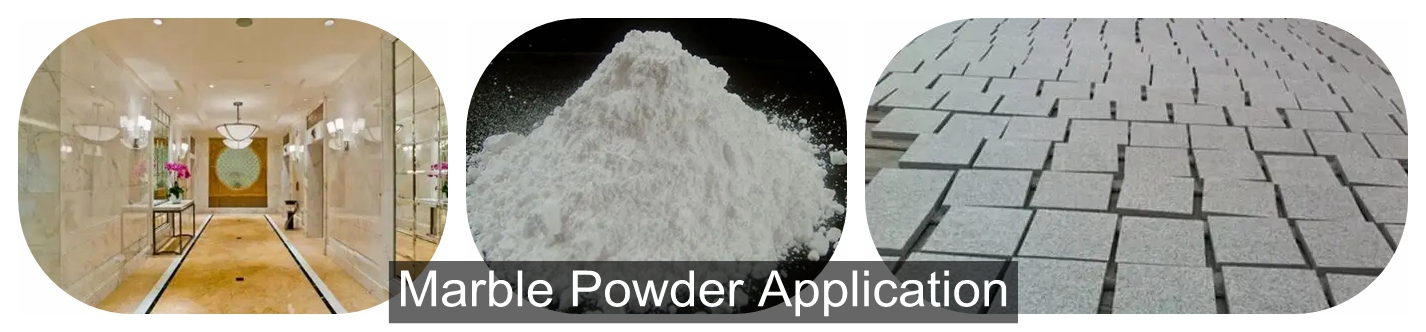

Marble, also known as dolomite, is a recrystallized limestone, as long as the component is CaCO 3. The limestone softens under high temperature and pressure, and recrystallizes when the minerals contained change to form marble. The main components are calcium and dolomite, with many colors, usually obvious patterns, and many mineral particles. The Mohs hardness is between 2.5 and 5 Marble powder is mainly used for processing into various shapes and plates, making walls, floors, platforms and columns of buildings, and often used as materials for memorial buildings such as monuments, towers and statues. It can also be carved into practical works of art such as arts and crafts, stationery, lamps and lanterns, and utensils

![]()

Marble crystal powder is a kind of crystal powder, the main component is calcium magnesium salt, and the chemical property is relatively unstable. After renovation and polishing, the process (vitrification) is adopted to increase the surface hardness. The purpose is to solidify the surface molecular structure, increase the wear resistance and strengthen the surface hardness of marble Marble crystal powder can decompose the calcium carbonate on the marble surface and make it free from the stone structure. Then, the active ions in the crystal powder react with the dissolved calcium ions on the surface to produce hard and dense calcified crystals. Therefore, the surface layer after crystallization will be more wear-resistant and not easy to scratch If properly treated, the crystallized surface layer will be dense and good, which will improve the gloss, antifouling and waterproof of the stone.

Large blocks of marble are transported to the raw material warehouse by special vehicles, and then the materials are sent to the jaw crusher by forklift / manual for crushing, and the crushing is smaller than the maximum feeding size of the pulverizer. The marble crushed by the crusher is lifted to the storage hopper by the elevator, and the storage hopper is discharged and then fed to the main machine by the feeder. The qualified products in the grinding process are screened by the screening system and then enter the collector through the pipeline. After being collected, they are discharged through the powder outlet pipe to be finished products. The unqualified products fall into the main machine for re grinding. The purified air flows into the blower through the residual air pipe above the dust remover. The air path is circulating. Except for the positive pressure from the blower to the grinding room, the air flow in the other pipes flows under negative pressure. The indoor sanitary conditions are good.