For product information and pricing, Chat with sales agent:

or email us : sales@clirik.com

Click links below to see related products.

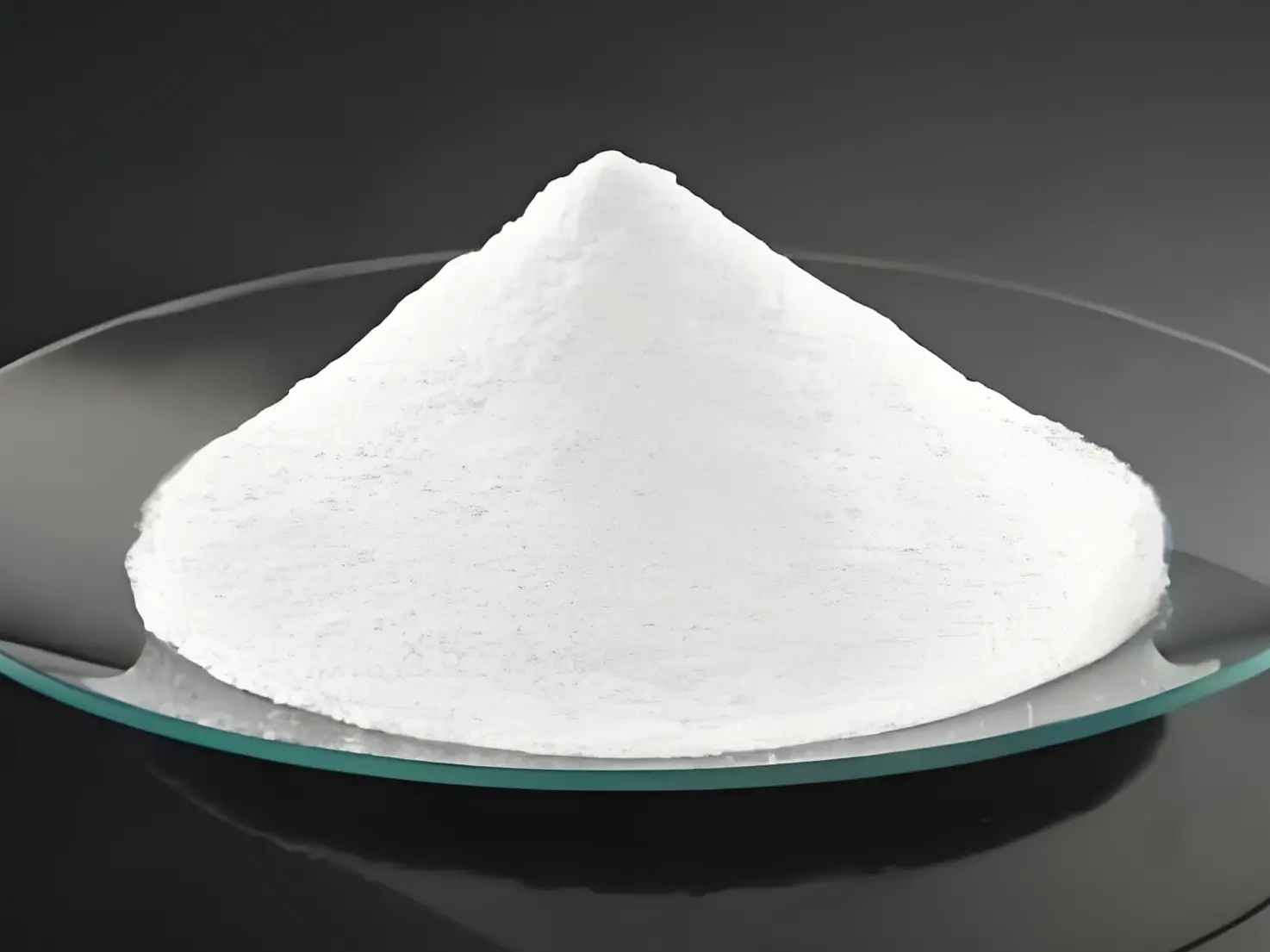

Magnesium oxide (MgO) is a versatile material with a wide range of applications in various industries, including metallurgy, construction, chemicals, and pharmaceuticals.

Depending on the specific requirements of these industries, magnesium oxide can be processed in different forms, such as light-burned (calcined) magnesium oxide and dead-burned (sintered) magnesium oxide.

Each form has unique properties and applications, necessitating specialized processing techniques.

The HGM series ultrafine grinding mill, offered by Shanghai CLIRIK Machinery Co., Ltd., is a highly efficient and versatile solution for processing both light-burned and Dead-burned magnesium oxide.

Light-burned magnesium oxide, also known as calcined magnesium oxide, is produced by calcining magnesium carbonate or magnesium hydroxide at temperatures ranging from 700 to 1000°C. This process results in a highly reactive form of magnesium oxide with the following characteristics:

1. High Reactivity: Light-burned magnesium oxide is highly reactive due to its porous structure and high surface area. This makes it ideal for applications requiring high chemical reactivity, such as in the production of magnesium salts and as a neutralizing agent in chemical processes.

2. Low Density: The calcination process produces a lightweight, porous material with a density of approximately 2.94 g/cm³. This low density makes it suitable for applications where weight is a critical factor.

3. Fine Particle Size: Light-burned magnesium oxide typically has a fine particle size, which enhances its reactivity and dispersibility in various applications.

4. Solubility: It is more soluble in acids and ammonium salts compared to Dead-burned magnesium oxide, making it suitable for applications in the chemical and pharmaceutical industries.

Dead-burned magnesium oxide, also known as sintered magnesium oxide, is produced by calcining magnesium carbonate or magnesium hydroxide at higher temperatures, typically between 1400 and 1800°C. This process results in a denser, less reactive form of magnesium oxide with the following characteristics:

1. High Density: Dead-burned magnesium oxide has a higher density, around 3.58 g/cm³, due to the sintering process that compacts the material into a dense structure.

2. Low Reactivity: The high-temperature sintering process reduces the material's reactivity, making it more stable and suitable for high-temperature applications.

3. High Melting Point: With a melting point of approximately 2800°C, Dead-burned magnesium oxide is ideal for use in refractory materials and high-temperature industrial processes.

4. Low Solubility: It is less soluble in water and acids compared to light-burned magnesium oxide, which makes it suitable for applications where chemical stability is crucial.

The HGM series ultrafine grinding mill from Shanghai CLIRIK Machinery Co., Ltd. is designed to meet the diverse needs of magnesium oxide processing. Whether you require light-burned or Dead-burned magnesium oxide, the HGM mill can efficiently grind the material to the desired fineness. Here are the key features and advantages of the HGM ultrafine grinding mill:

1. High Fineness and Precision: The HGM mill can achieve a fineness range of 200 to 2500 mesh (6 to 74 microns), making it suitable for producing both fine and ultra-fine magnesium oxide powders. This level of precision is crucial for applications in high-end paints, electronics, and pharmaceuticals.

2. Efficient and Energy-saving: The HGM mill is highly efficient, with a capacity ranging from 0.5 to 45 tons per hour. It consumes 30% less energy compared to traditional grinding equipment, making it an environmentally friendly and cost-effective choice.

3. Wide Range of Applications: The mill can process a wide range of non-metallic minerals with Mohs hardness below 7 and humidity under 6%. This includes materials such as calcite, talc, mica, kaolin, and both light-burned and Dead-burned magnesium oxide.

4. Low Noise and Environmental Protection: The HGM mill operates smoothly with low noise levels, creating a clean and safe working environment. Its closed-circuit air circulation system reduces the introduction of fresh air and minimizes the contact between magnesium oxide and water vapor in the air, helping to maintain the purity of the material.

5. Easy Operation and Maintenance: The mill is equipped with an advanced control system that allows for easy operation and precise control over the grinding process. Its design ensures easy maintenance, with accessible components and a user-friendly interface.

6. Customizable Solutions: Shanghai CLIRIK Machinery Co., Ltd. offers a range of models within the HGM series to meet different production needs. The company also provides customized solutions based on specific customer requirements, ensuring that each mill is tailored to meet the unique needs of the application.