For product information and pricing, Chat with sales agent:

or email us : sales@clirik.com

Click links below to see related products.

Titanium dioxide is an important inorganic chemical pigment. The production process of titanium dioxide has two process routes: sulfuric acid method and chlorination method. It has important uses in coatings, inks, papermaking, plastics and rubbers, chemical fibers, ceramics, and other industries.

Titanium Dioxide

Titanium dioxide is a widely used chemical raw material with extremely high economic value. Therefore, it is of great significance to study the production process of titanium dioxide. This article introduces the current production technology of titanium dioxide.

The production process of titanium dioxide is divided into three steps: raw material pretreatment, production process, and post-production treatment. The following three sections will be introduced in detail.

The raw material for the production of titanium dioxide is rutile, which can be produced in gneiss, pegmatite, eclogite (amphibious) rock mass and placer.

The first step is to pulverize the rutile, which is generally used in YGM high-pressure grinding mill.

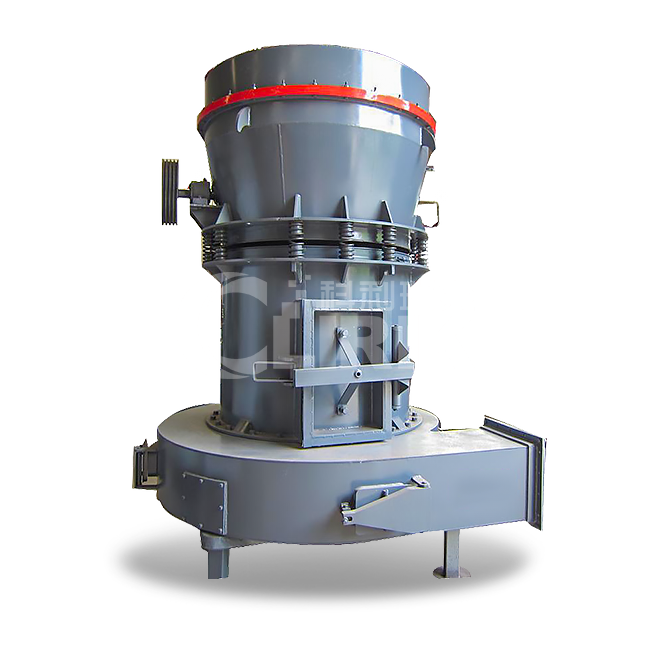

Titanium dioxide high pressure grinding machine

The rutile enters the high-pressure mill, and the material is scooped up by the shovel and sent to the grinding belt formed by the grinding roller and the grinding ring.

The grinding device is equipped with a high-pressure spring, which increases the grinding force between the grinding roller and the grinding ring by 1.2 times, reduces the frequency of the back and forth swinging of the grinding roller device, increases the stability and improves the working efficiency of the mill.

YGM high-pressure grinding mill

The high-pressure pulverizer has a high-pressure spring pressure device inside, which increases the grinding pressure of the roller by 800-1200kg under the action of the high-pressure spring. Compared with other pulverizers, the production capacity under the same power condition is also increased by 20%. -30%.

The grinding roller device in the high-pressure grinding mill adopts overlapping multi-stage sealing, which has good sealing performance and more environmentally friendly dust removal effect.

The crushed rutile enters the acid hydrolysis tank and undergoes acid hydrolysis with the prepared concentrated sulfuric acid. During the acid hydrolysis, air pressure is first performed, and then the rutile is stirred with the sulfuric acid for about half an hour. After the reaction is completed, continue the air pressure for 10-15 minutes, start to invade, add the metered water into the acidolysis tank, and dissolve the solid phase.

This process is also about three hours. After the junction speed is invaded, a certain amount of elemental iron is added to reduce the ferric ions in the titanium solution.

When trivalent titanium appears in the solution, a flocculant is added. Continue to pour the black titanium liquid into the sedimentation tank, after sedimentation and filtration, the titanium liquid is poured into the titanium liquid preheating tank.

Then comes the hydrolysis part.

In the hydrolysis part, firstly, seed crystals are prepared, and the titanium liquid obtained by acid hydrolysis and alkali liquid are heated and mixed in the seed crystal preparation tank to prepare seed crystals, and then the seed crystals are added to the titanium liquid preheating tank and stirred.

Then, the titanium liquid in the titanium liquid preheating tank is injected into the hydrolysis pot for hydrolysis;

The hydrolyzed titanium liquid enters the metatitanic acid storage tank and starts a wash;

After washing, the metatitanic acid is beaten into the bleaching process, the bleached metatitanic acid is rinsed, and after rinsing, salt treatment is performed, and after the salt treatment is completed, the pre-kiln pressing is started;

The pressed water and titanium dioxide are transferred into the kiln body, and calcination is started. After the calcination is completed, it is cooled by a cooling kiln, and finally pulverized by a high-pressure pulverizer to obtain the final product titanium dioxide.

Shanghai CLIRIK Machinery Co.,Ltd. has been committed to the field of ultra-fine powder grinding machines for 20 years.

CLIRIK has a first-class manufacturing base with standardized and intelligent production lines.

CLIRIK's professional R&D, sales, installation and after-sales teams have provided door-to-door services to more than 100 countries and regions.

HGM grinding mill: 74-5 micron(200-2500 mesh); D97=5 micron

YGM Raymond mill: 613-33 micron(30-325 mesh); D90=30 micron

CLUM vertical roller mill: 20-5 micron(600-3000 mesh); D50=2 micron D97=4 micron

You can leave a message online or contact CLIRIK directly:

Email: sales@clirik.com

WhatsApp: +8613512155195/+8613917147829