For product information and pricing, Chat with sales agent:

or email us : sales@clirik.com

Click links below to see related products.

Making diabase powder involves a series of steps, including extraction, crushing, and grinding. Here's a general guide on how diabase powder is typically produced:

l Location Selection: Identify and select a diabase quarry based on geological surveys and considerations.

l Extraction: Use heavy machinery such as excavators and bulldozers to remove overburden and extract diabase blocks from the quarry.

l Loading and Hauling: Load extracted diabase blocks onto trucks for transportation to the processing facility.

l Transportation: Deliver the diabase blocks to the processing site.

l Jaw Crushers: Use jaw crushers to break down large diabase blocks into smaller, manageable sizes.

l Cone Crushers and Impact Crushers: Further reduce the size of diabase particles through secondary and tertiary crushing stages.

l Vibrating Screens: Classify the crushed diabase into different particle sizes, separating finer particles from coarser ones.

The first step in selecting grinding equipment is to determine the desired particle size of the diabase powder. Different applications may require different particle sizes, and the grinding equipment must be chosen accordingly.

Consider the intended application of the diabase powder. For example, if the powder is destined for use in construction materials like concrete, a specific particle size distribution may be required for optimal performance.

Evaluate the production capacity needed for the processing facility. This consideration helps in choosing grinding equipment that can handle the required throughput efficiently.

Assess the energy efficiency of the grinding equipment. Modern grinding mills often come with advanced technologies to optimize energy consumption, contributing to cost-effectiveness and environmental sustainability.

Consider the ease of maintenance and the durability of the equipment. Robust and well-maintained machines contribute to consistent and reliable performance.

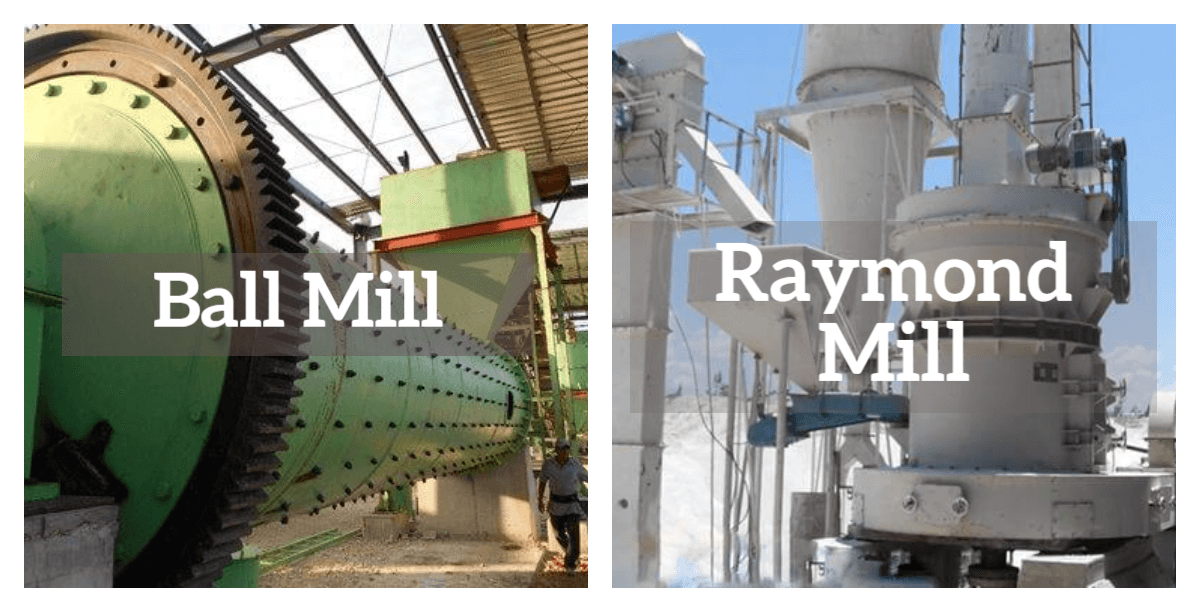

l Operation: Ball mills use rotating cylinders filled with balls to grind the diabase. The rotation causes the balls to cascade and grind the material. This method is effective for coarse to fine grinding.

l Application: Ball mills are versatile and commonly used for a wide range of applications due to their simplicity and effectiveness.

l Operation: Raymond mills have a central feed pipe, and the diabase is crushed between rotating grinding rollers and a stationary grinding ring. This results in a finely powdered product.

l Application: Raymond mills are suitable for various applications, including mineral processing and industrial applications.

l Operation: Vertical roller mills have a rotating table and rollers that crush diabase between them. The crushed material is carried away by the airflow for further classification. VRMs are effective for producing fine powder with a narrow particle size distribution.

l Application: Vertical roller mills are often used for cement and mineral grinding, where a high degree of fineness is required.

l Operation: Ultrafine mills use high-speed impact and shearing forces to reduce diabase to extremely fine particles. They often include air classifiers to control particle size.

l Application: Ultrafine mills are used when an exceptionally fine particle size is required, such as in the production of high-performance materials.

Adjustment: Fine-tune the grinding process to achieve the desired particle size distribution for specific applications.

Testing: Perform quality control tests to ensure the diabase powder meets specifications for particle size, composition, and other relevant properties.

Inspection: Visually inspect the diabase powder for any impurities or irregularities.

Packaging: Package the diabase powder in appropriate containers for distribution.

Storage: Store the packaged diabase powder in a controlled environment to prevent contamination or moisture absorption.

Distribution: Transport the diabase powder to end-users, construction sites, or manufacturing facilities.

Application: Use diabase powder in various applications, such as in the production of concrete, asphalt, dimension stone, or artistic and decorative elements.

Dust Control: Implement dust control measures, including dust collection systems, to minimize airborne particles during the crushing and grinding processes.

Environmental Compliance: Adhere to environmental regulations and best practices to ensure sustainable and responsible diabase processing.

Shanghai Clirik Machinery Co.,Ltd. specializes in the production of various diabase crushing and grinding equipment. Welcome to contact us for more information about diabase processing.