For product information and pricing, Chat with sales agent:

or email us : sales@clirik.com

Click links below to see related products.

When it comes to industrial mineral processing, the term “rock pulverizer machine” refers to advanced grinding equipment that reduces rock materials to micron and sub-micron fineness.

Whether you're working with limestone, marble, talc, barite, dolomite, gypsum, or other non-metallic minerals, having the right pulverizing solution is key to achieving high efficiency, low operating cost, and consistent particle size.

Shanghai Clirik Machinery Co., Ltd., a leading manufacturer in China, has set itself apart with its world-class grinding mill technologies.

Over the past two decades, Clirik has developed a comprehensive range of rock pulverizer machines designed to meet different fineness, capacity, and energy-efficiency requirements.

In this article, we explore three of Clirik’s most sought-after models: HGM ultrafine grinding mill, CLRM Raymond mill, and CLUM ultrafine vertical roller mill—each engineered for specific industrial grinding needs.

The HGM series ultrafine grinding mill is Clirik’s flagship model for producing superfine powder ranging from 150 to 3000 mesh (5–74 microns). It is a multi-ring roller mill that offers highly efficient, stable, and fine grinding performance, especially for soft to medium-hard rocks.

Model Options: HGM80, HGM100, HGM125, HGM168L

Finished Product Size: 5–74 μm

Capacity: 0.5–45 t/h

Main Motor Power: 55–315 kW

Fineness Control: Adjustable by frequency converter or PLC system

Multi-layer grinding ring design increases grinding efficiency while minimizing energy consumption.

Utilizes a pulse dust collector and sound insulation structure for clean and quiet operation.

Advanced classifier system ensures consistent particle size distribution.

Suitable for non-flammable, non-explosive minerals with Mohs hardness below 6.

Can handle a wide range of materials such as calcium carbonate, kaolin, dolomite, barite, talc, mica, feldspar, and fluorite.

Paints and coatings

Plastics and rubber filler

Paper industry

Construction materials

Environmental materials (desulfurization, soil remediation)

If your focus is on producing high-purity, ultrafine powder with tight particle control, the HGM mill is a reliable choice. Its cost-effectiveness, simple maintenance, and fully automated system make it ideal for small to mid-sized production lines.

The CLRM series Raymond mill is Clirik’s upgraded version of the traditional Raymond mill, engineered with improved performance, reduced power consumption, and better environmental protection.

This type of rock pulverizer machine is most suitable for grinding materials into 60–325 mesh (20–180 μm), making it ideal for industries that do not require ultrafine fineness but still demand precision and reliability.

Model Options: CLRM-613, CLRM-7128, CLRM-8530

Finished Product Size: 20–180 μm

Capacity: 1–20 t/h

Main Motor Power: 22–110 kW

Grinding Rollers: 3–5 depending on the model

Traditional pendulum structure with stronger rollers for longer lifespan.

Integrated air blower, classifier, and cyclone collector system.

Lower initial investment and easy installation.

Equipped with a dedusting system to ensure eco-friendly operation.

Cement and construction

Ceramics

Metallurgical industries

Paint and pigment production

Lime and desulfurization applications

The CLRM Raymond mill offers a perfect balance between cost and performance, suitable for operations that do not need ultra-fine powder but value reliability and ease of use. It is especially popular among SMEs and developing markets due to its simple structure and low maintenance requirements.

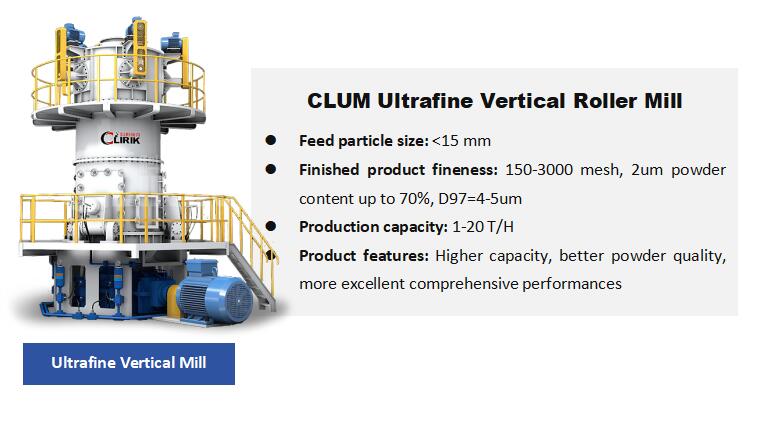

If you’re looking for a next-generation rock pulverizer machine, Clirik’s CLUM series ultrafine vertical roller mill delivers industrial-grade output with superior precision.

Designed for production capacities up to 30 tons per hour, the CLUM mill is ideal for large-scale manufacturers focused on 2–45 μm ultrafine powder.

This vertical mill integrates grinding, grading, and conveying in a single unit, reducing the system footprint while improving efficiency and stability.

Model Options: CLUM1425, CLUM1632, CLUM1736

Finished Product Size: 2–45 μm

Capacity: 3–30 t/h

Main Motor Power: 250–315 kW

Vertical Integration: Grinding + Classifying + Drying

Uses multi-head classifier technology to achieve narrow particle size distribution.

Designed with roller lubrication system, auto control system, and PLC interface for intelligent operation.

Low vibration and noise level compared to traditional ball mills or jet mills.

Environmentally friendly, with closed circulation air system and high dust collection efficiency.

Optional surface modification machine (coating machine) for powder enhancement.

High-end filler (e.g., PVC, cable, plastics)

Functional powder in paints and ink

Ceramic raw materials

Paper and printing industries

Precision grinding in electronics and semiconductor industries

The CLUM series is designed for demanding customers who require high productivity, extremely fine powder, and stable long-term operation. It is the preferred choice in fields such as nanotechnology materials, advanced coatings, and functional powders.

Model | Fineness Range | Capacity | Best For |

HGM Ultrafine Mill | 150–3000 mesh | 0.5–45 t/h | Medium-to-ultrafine powder (paint, plastics, etc.) |

CLRM Raymond Mill | 60–325 mesh | 1–20 t/h | Coarse-to-medium powder (cement, lime, etc.) |

CLUM Vertical Mill | 2000–325 mesh (2–45 μm) | 3–30 t/h | High-end ultrafine powder (functional filler, coatings, etc.) |

Clirik’s rock pulverizer machines are trusted by customers in over 50 countries, including India, Brazil, Egypt, France, Nigeria, and Indonesia. The company provides:

On-site installation & training

Spare parts supply

Technical consulting and after-sales support

Customization services to match different raw materials and plant sizes

Clirik also offers turnkey solutions, helping clients build full production lines with feeders, conveyors, dust collectors, storage systems, and coating machines.

Here are a few reasons Clirik stands out in the rock pulverizer machine industry:

Over 20 years of experience in grinding mill R&D and manufacturing.

ISO9001:2015 and CE certified equipment.

100+ professional engineers for installation and after-sales.

Fully customizable systems based on your raw material and production needs.

Consistent investment in innovation and energy-saving technology.

Whether you’re running a small operation or a large-scale industrial plant, Clirik has the right rock pulverizer machine for your project.

From HGM ultrafine mills designed for micron-level precision, to the CLRM Raymond mill for cost-effective grinding, to the CLUM vertical roller mill for high-capacity, high-end ultrafine production, Clirik offers comprehensive grinding solutions.

Ready to take your powder processing to the next level?

Contact Clirik Today:

www.clirik.com

Email: info@clirik.com

WhatsApp: +8613512155195