For product information and pricing, Chat with sales agent:

or email us : sales@clirik.com

Click links below to see related products.

Calcium hydroxide, a versatile compound with multifaceted applications across industries, requires finely ground particles to meet stringent specifications.

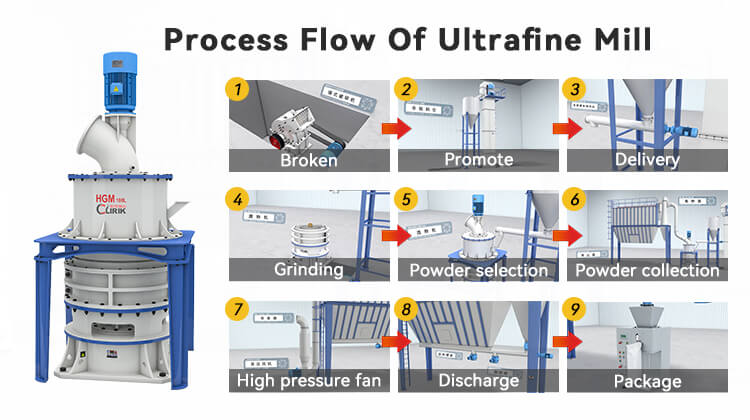

HGM ultrafine grinding mill is capable of processing calcium hydroxide into ultrafine powder within the range of 325-800 mesh. This mill is designed specifically for producing ultrafine powders, making it suitable for various materials including calcium hydroxide. Its high efficiency and precision make it ideal for grinding such fine materials to the desired particle size range.

HGM ultrafine mill is a type of grinding equipment designed to produce extremely fine particles. It is used for processing a wide range of materials, including minerals, chemicals, and other industrial products. Ultrafine mills are characterized by their ability to achieve very high fineness levels, precise particle size control, and efficient particle size reduction.

The HGM mill operates on the principle of high-speed impact grinding, where feed material undergoes rapid comminution through intense collisions and frictional forces.

Utilizing high-speed rotating discs or jets of air, the HGM mill imparts kinetic energy to the feed material, resulting in efficient particle size reduction to the submicron level.

With its advanced grinding mechanism and precision classifier system, the HGM mill offers precise control over particle size distribution, enabling the production of particles within the 325-800 mesh range.

The classifier system ensures uniform particle size distribution, essential for applications requiring consistency and accuracy.

Despite its high-speed grinding mechanism, the HGM mill is designed to be energy-efficient, minimizing energy consumption per unit of material processed.

Efficient airflow management and optimized grinding parameters contribute to reduced energy requirements, enhancing operational sustainability.

The HGM ultrafine grinding mill finds application across diverse industries, including minerals processing, chemicals, pharmaceuticals, and advanced materials manufacturing.

Its versatility allows for the processing of various materials, from soft to highly abrasive, making it a versatile solution for a wide range of grinding tasks.

The utilization of the HGM ultrafine grinding mill for processing calcium hydroxide into the 325-800 mesh range presents several advantages and considerations:

The HGM mill offers precise control over particle size distribution, enabling the production of calcium hydroxide particles within the desired mesh range with exceptional uniformity and consistency.

Leveraging its advanced grinding mechanism, the HGM mill achieves ultrafine particle sizes suitable for various industrial applications, including coatings, plastics, and pharmaceutical formulations.

Ultrafine calcium hydroxide particles produced by the HGM mill exhibit increased surface area and reactivity, making them ideal for applications requiring rapid dissolution and chemical reactions.

Despite its advanced features, the HGM ultrafine grinding mill offers cost-effective operation and maintenance, providing a favorable return on investment for industrial-scale calcium hydroxide processing.

The finely ground calcium hydroxide produced by the HGM mill finds application across various industries and applications:

l Construction Materials: Fine calcium hydroxide particles are used in the production of paints, coatings, and adhesives for construction applications.

l Environmental Remediation: Ultrafine calcium hydroxide is employed in environmental remediation processes for wastewater treatment, soil stabilization, and air pollution control.

l Chemical Synthesis: Precisely ground calcium hydroxide serves as a key ingredient in chemical synthesis, including the production of catalysts, pharmaceuticals, and specialty chemicals.

The utilization of the HGM ultrafine grinding mill for processing calcium hydroxide into the 325-800 mesh range represents a leap forward in precision grinding technology. By harnessing its advanced features, including precise particle size control, ultrafine particle sizes, and enhanced reactivity, industries can unlock new avenues for innovation and efficiency. As the demand for finely ground materials continues to rise, the HGM mill stands as a testament to precision engineering and technological advancement, driving progress in industrial processing and product development.

Shanghai Clirik Machinery Co., Ltd., as a leader in the field of calcium hydroxide grinding mills, has always been committed to providing customers with efficient, stable and reliable grinding solutions.

Our products are not only widely used in mining, construction materials, chemicals, metallurgy, transportation, hydraulic engineering and other industries, but also have won the favor of a large number of users with their excellent grinding effect, flexible adaptability and excellent performance indicators. Welcome to leave a message for consultation.