For product information and pricing, Chat with sales agent:

or email us : sales@clirik.com

Click links below to see related products.

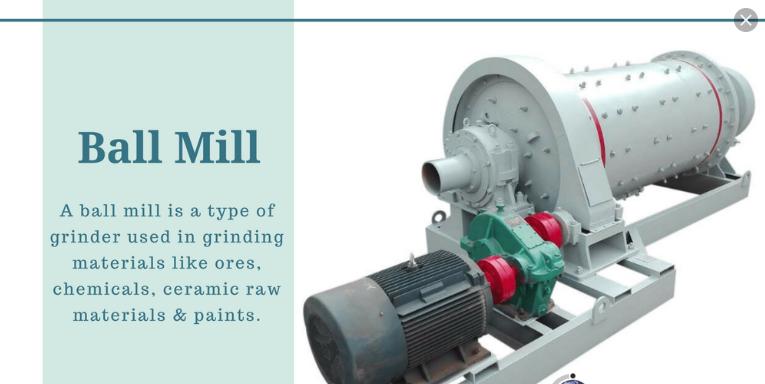

Ultra ball grinder also named ultra-fine powder ball mill , it is a commonly used ball mill in ore dressing production.Ultra ball grinder is suitable for grinding various ores and other materials.

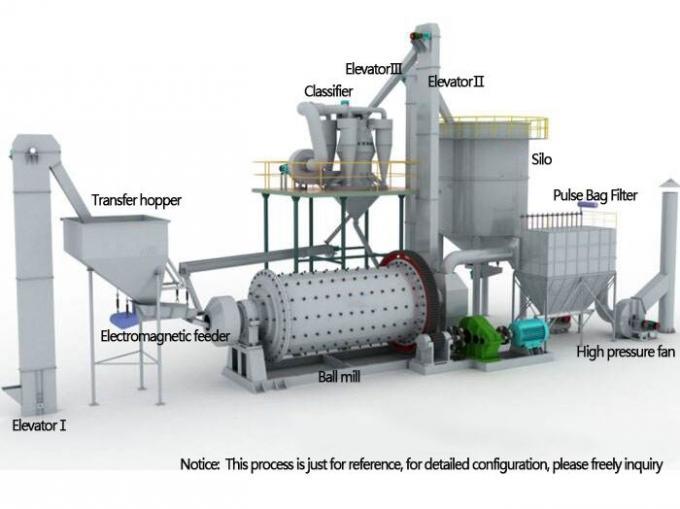

The superfine ball mill technology is perfectly combined with the self-distributing fine powder classification technology to form a new energy-saving, high-efficiency, and environmentally-friendly superfine grinding production line.

The ultra-fine powder ball mill has a wide range of applications and can process various metal ores and non-metal ores. Common ones include gold, silver, copper, iron, molybdenum, phosphate, feldspar, fluorite, cement, marble and other building stones, etc.

Ultra ball grinders are widely used in mineral processing production lines, building materials, chemicals, mining, cement, white ash, fly ash, pigments and other powder processing industries.

| Models | Speed | Load of Ball | Input Size | Output Size | Capacity | Power | Weight |

| (r/min) | (t) | (mm) | (mm) | (t/h) | (kw) | (t) | |

| Ф900×1800 | 36-38 | 1.5 | less than 20 | 0.075-0.89 | 0.65-2 | 18.5 | 5.85 |

| Ф900×3000 | 36 | 2.7 | less than 20 | 0.075-0.89 | 1.1-3.5 | 22 | 6.98 |

| Ф1200×2400 | 36 | 3 | less than 25 | 0.075-0.6 | 1.5-4.8 | 30 | 13.6 |

| Ф1200×3000 | 36 | 3.5 | less than 25 | 0.074-0.4 | 1.6-5 | 37 | 14.3 |

| Ф1200×4500 | 32.4 | 5 | less than 25 | 0.074-0.4 | 1.6-5.8 | 55 | 15.6 |

| Ф1500×3000 | 29.7 | 7.5 | less than 25 | 0.074-0.4 | 44232 | 75 | 19.5 |

| Ф1500×4500 | 27 | 11 | less than 25 | 0.074-0.4 | 44261 | 110 | 22 |

| Ф1500×5700 | 28 | 12 | less than 25 | 0.074-0.4 | 3.5-6 | 130 | 25.8 |

| Ф1830×3000 | 25.4 | 11 | less than 25 | 0.074-0.4 | 44296 | 130 | 34.5 |

| Ф1830×4500 | 25.4 | 15 | less than 25 | 0.074-0.4 | 4.5-12 | 155 | 38 |

| Ф1830×6400 | 24.1 | 21 | less than 25 | 0.074-0.4 | 6.5-15 | 210 | 43 |

| Ф1830×7000 | 24.1 | 23 | less than 25 | 0.074-0.4 | 7.5-17 | 245 | 43.8 |

| Ф2100×3000 | 23.7 | 15 | less than 25 | 0.074-0.4 | 6.5-36 | 155 | 45 |

| Ф2100×4500 | 23.7 | 24 | less than 25 | 0.074-0.4 | 8-43 | 245 | 56 |

| Ф2100×7000 | 23.7 | 26 | less than 25 | 0.074-0.4 | 12-48 | 280 | 59.5 |

| Ф2200×4500 | 21.5 | 27 | less than 25 | 0.074-0.4 | 9-45 | 280 | 54.5 |

| Ф2200×6500 | 21.7 | 35 | less than 25 | 0.074-0.4 | 14-26 | 380 | 61 |

| Ф2200×7000 | 21.7 | 35 | less than 25 | 0.074-0.4 | 15-28 | 380 | 62.5 |

| Ф2200×7500 | 21.7 | 35 | less than 25 | 0.074-0.4 | 15-30 | 380 | 64.8 |

| Ф2400×3000 | 21 | 23 | less than 25 | 0.074-0.4 | 7-50 | 245 | 58 |

| Ф2400×4500 | 21 | 30 | less than 25 | 0.074-0.4 | 8.5-60 | 320 | 72 |

| Ф2700×4000 | 20.7 | 40 | less than 25 | 0.074-0.4 | 22-80 | 380 | 95 |

| Ф2700×4500 | 20.7 | 48 | less than 25 | 0.074-0.4 | 26-90 | 480 | 102 |

| Ф3200×4500 | 18 | 65 | less than 25 | 0.074-0.4 | According to the process conditions | 630 | 149 |

| Ф3600×4500 | 17 | 90 | less than 25 | 0.074-0.4 | According to the process conditions | 850 | 169 |

| Ф3600×6000 | 17 | 110 | less than 25 | 0.074-0.4 | According to the process conditions | 1250 | 198 |

| Ф3600×8500 | 18 | 131 | less than 25 | 0.074-0.4 | 45.8-256 | 1800 | 260 |

| Ф4000×5000 | 16.9 | 121 | less than 25 | 0.074-0.4 | 45-208 | 1500 | 230 |

| Ф4000×6000 | 16.9 | 146 | less than 25 | 0.074-0.4 | 65-248 | 1600 | 242 |

| Ф4000×6700 | 16.9 | 149 | less than 25 | 0.074-0.4 | 75-252 | 1800 | 249 |

| Ф4500×6400 | 15.6 | 172 | less than 25 | 0.074-0.4 | 84-306 | 2000 | 280 |

| Ф5030×6400 | 14.4 | 216 | less than 25 | 0.074-0.4 | 98-386 | 2500 | 320 |

| Ф5030×8300 | 14.4 | 266 | less than 25 | 0.074-0.4 | 118-500 | 3300 | 403 |

| Ф5500×8500 | 13.8 | 338 | less than 25 | 0.074-0.4 | 148-615 | 4500 | 525 |