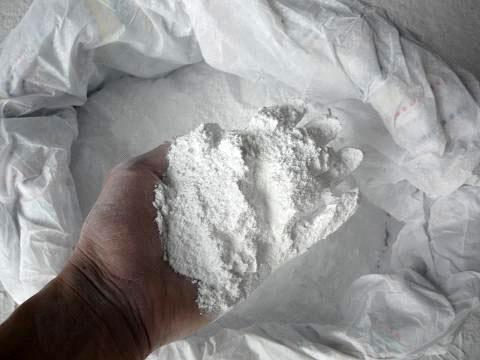

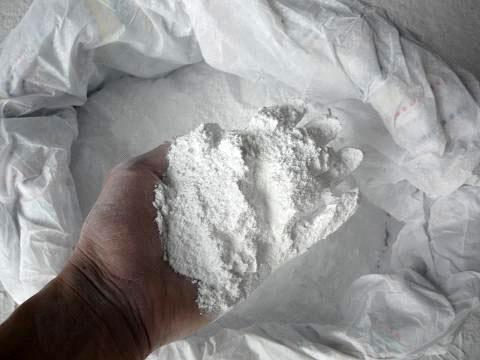

About heavy calcium carbonate

Heavy calcium carbonate also name ground calcium carbonate, ground CaCO3 or GCC.

Heavy calcium carbonate powder is a powdered form of heavy calcium carbonate. The main component is calcium carbonate, which has the characteristics of high purity, stable chemical properties and soft hue.

Heavy calcium carbonate has a wide range of applications and can be widely used in daily chemical industries such as rubber, plastics, paper, coatings, paints, inks, etc. It plays a very important role in the development of the national economy.

Heavy calcium carbonate processing machines

In order to meet the production needs of various fields, heavy calcium carbonate must be processed by crushing, grinding and other procedures.

At this time, heavy calcium carbonate grinders are used. According to the requirements of different finished product particle sizes, users can choose various types of heavy calcium carbonate grinders.

The processing of heavy calcium carbonate powder is used in various industries, and a grinding mill is generally required to grind calcite to between 325 mesh and 1000 mesh.

According to different industries, the fineness of grinding needs to be adjusted accordingly.

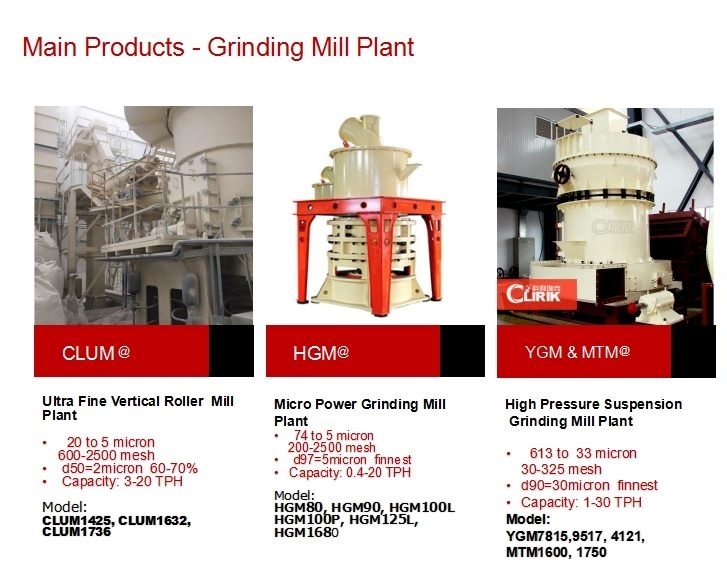

CLIRIK heavy calcium carbonate grinding mill equipment

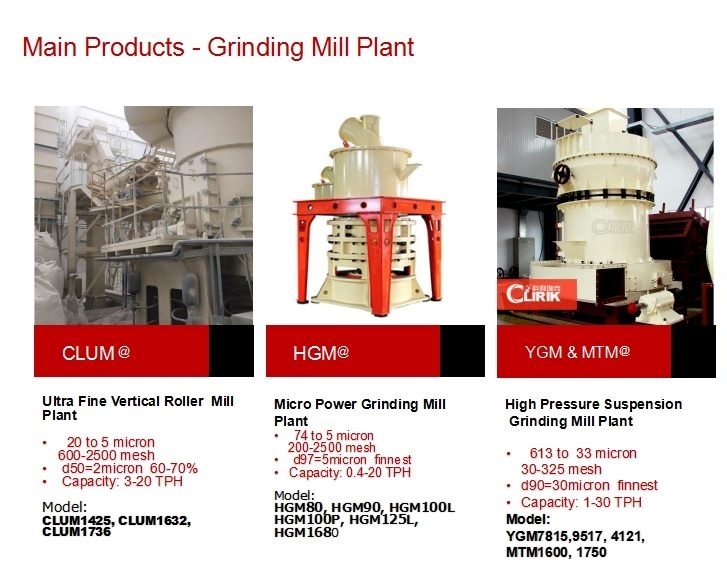

According to this situation, the Clirik grinidng mill equipment includes:

YGM high-pressure Raymond grinding mill,

HGM three-ring ultra-fine grinding mill and

CLUM ultra-fine vertical roller grinding mill.

CLIRIK YGM high-pressure Raymond grinding mill, HGM three-ring ultrafine grinding mill and CLUM ultra-fine vertical roller grinding mill improve the grinding system for heavy calcium carbonate powder grinding.

The improved heavy calcium carbonate powder mill can effectively increase the grinding particle size, and can realize the integrated operation of crushing, grinding, drying, grading and conveying materials, effectively improving production efficiency and meeting the needs of large-scale enterprises for processing and production.

At the same time, the ultra-fine pulverizer can use a large processing capacity, which can meet the 1250 mesh single-wheel classifier. CLIRIK grinding mills are widely used in the non-metallic mining industry.

CLIRIK grinding mills have a series of advantages such as stable performance, wide application range, simple structure, convenient operation, large processing capacity, and energy saving. It is a high-tech grinding product.

Which models can be selected for processing heavy calcium carbonate powder?

Heavy calcium carbonate Raymond mill

Raymond heavy calcium carbonate grinder is a kind of Raymond mill.

It is a high-efficiency grinding equipment developed mainly for the grinding characteristics of heavy calcium carbonate.

It has a very good effect on the grinding of heavy calcium carbonate.

The heavy calcium carbonate grinder is a vertical structure with a very small area, which can save users the cost of land investment.

The finished product particle size of the heavy calcium carbonate Raymond mill can be adjusted arbitrarily within the range of 80 mesh to 325 mesh.

Compared with other equipment, the heavy calcium Raymond mill has a high through-screening rate of the finished product, up to 99%, and the finished product is in the shape of needles and flakes.

The content is low, and the content of the three-dimensional finished product is very high, which can greatly enhance the application value of the finished product.

The price of heavy calcium carbonate Raymond mill is cheap, the performance is excellent, and the price-performance ratio is very high.

Moreover, the heavy calcium carbonate mill is a kind of Raymond mill, which abandons the shortcomings of traditional Raymond mills and improves The value of the finished product reduces energy consumption and environmental pollution, and is generally welcomed by users.

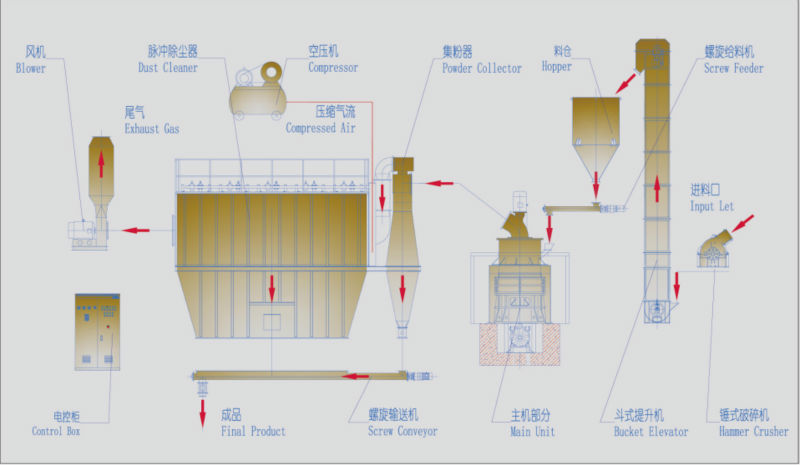

How to process heavy calcium carbonate powder by CLIRIK HGM ultrafine grinding mill?

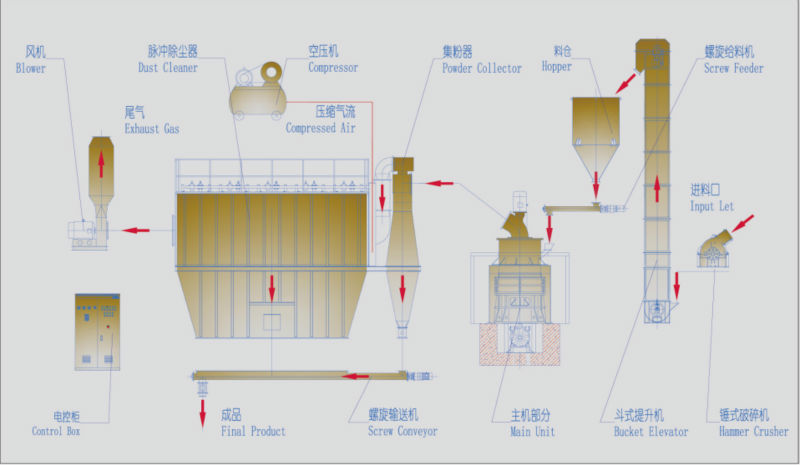

The grinding roller inside the equipment rolls in the grinding ring raceway.

The large pieces of calcium carbonate stone(such as limestone, calcite, marble, etc.) are crushed into small particles by the hammer crusher.

Then they are sent to the storage bin by the elevator.

Through the vibrating feeder and the inclined feeding pipe, the materials are evenly sent to the bulk tray on the upper part of the turntable.

The material is scattered to the periphery of the circle under the action of centrifugal force, and falls into the raceway of the grinding ring, and is impacted, rolled, and ground by the ring roller.

After three-layer ring processing, it becomes powder.

The high-pressure fan removes the external air through suction.

Inhale into the machine, and bring the crushed material into the powder concentrator.

Why choose CLIRIK?

-

The common choice of 1000+ customers, tailor-made solutions for you

-

More than 30 years of experience in R&D and manufacturing, and 120+ countries and regions coverage to jointly witness high-quality quality

-

Systematic and standardized process, safer and more efficient from service to preparation and delivery

-

Finished product analysis-project declaration-process design-material trial grinding-infrastructure guidance-installation and commissioning-training guidance-project acceptance-after-sales service

Here are 4 reasons to choose CLIRIK

1. Factory direct supply

The source manufacturer has no middleman, higher cost performance, large quantity and excellent quality, ingenuity

2. Ingenuity

Automatic equipment production, the pipe wall is thicker and resistant to compression and deformation, environmentally friendly materials are harmless, and support customization

3. Support customization

Can be specially designed according to customer requirements, support various environmental program customization, strictly inspect the quality before leaving the factory, and improve the service

4. Perfect service

One-stop pre-sales and after-sales service, on-site survey, on-site installation, 7x24 hours after-sales service

How to get the latest quotation?

You can leave a message online or contact CLIRIK directly:

Email: sales@clirik.com

WhatsApp: +8613512155195/+8613917147829