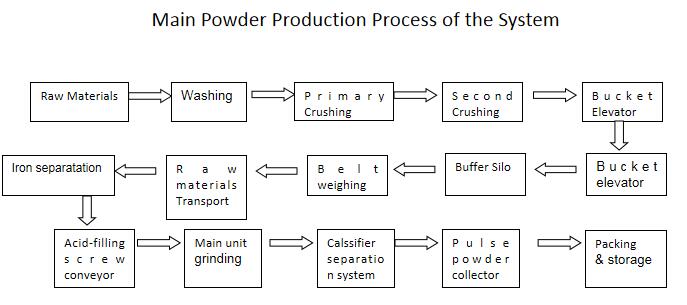

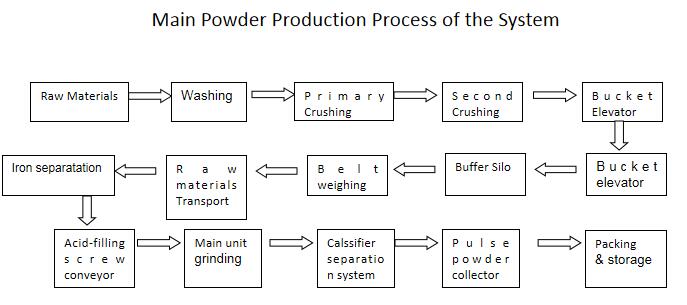

The ultrafine powder processing system process include raw material washing, primary crushing, iron separation, secondary crushing, raw materials storage, weighing, iron removing, medicine filling, ultrafine powders grinding, main unit classifying, pipe conveying, pulse bag filter powders collection, finished powders transporation, packaging, compressed air transporation system, power remote control system and PLC central control system etc.

1.Raw Material Washing

Ore washing is a process of scrubbing the ore cemented by clay or containing more mud by hydraulic or mechanical force, so that the ore is broken up, and the fine mud on the surface of the ore is washed and separated.

Commonly used ore washing equipment includes hydraulic ore washing screen, cylindrical washing machine, cylinder scrubbing machine, trough washing machine and so on.

2. Primary crushing

In the stone production line, the

jaw crusher is usually used as the first-level crusher to coarsely crush the stone.

3. Iron separation

The removal of iron from materials and mud is a very important link in the production process of electric porcelain. Generally, the factory has 1-2 times of iron removal process for dry powder material, and more than 2 times for mud removal process.

There are many methods for removing iron, including elutriation, hydrocyclone, pickling, electrophoresis separation, high-frequency induction, and magnetic separation.

4. Secondary crushing

In the stone production line, the

impact crusher is usually used as a secondary crusher to crush the stone.

5. Raw materials storage

6. Weighing

7. Iron removing

The magnetic separation method is widely used in production practice, which has the characteristics of simple process, high efficiency and low cost.

The iron removal equipment used in the production of electric porcelain is generally a magnetic separator.

8. Medicine filling

Because some powders are susceptible to moisture, the powders are not easy to disperse in water, need a certain curing time, and it is not easy to clean up when scattered outside. A dosing device is needed.

The commonly used equipment is a screw conveyor for dosing

9. Ultrafine powders grinding

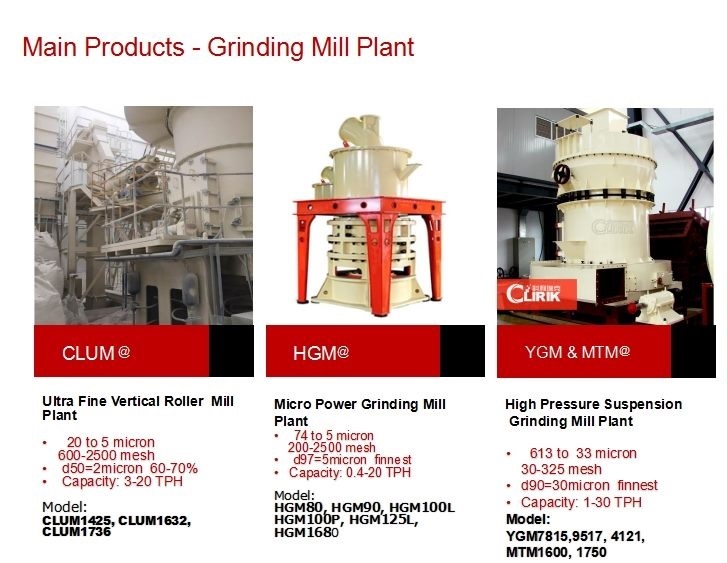

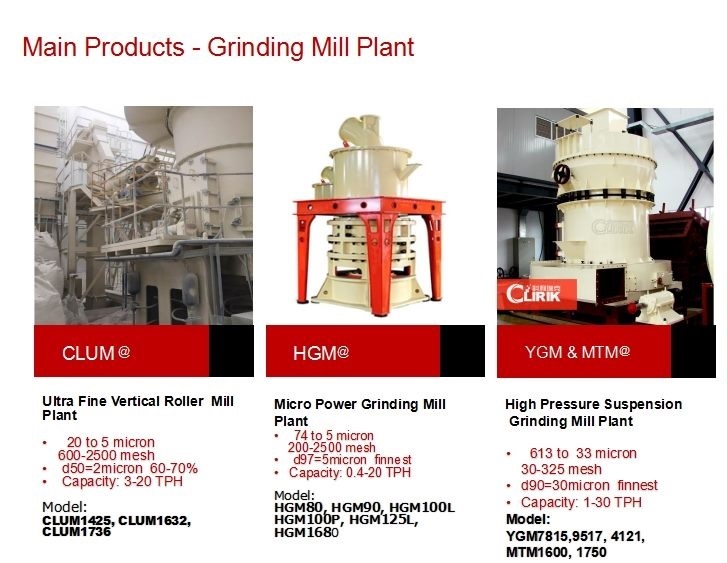

Ultrafine powder grinding equipment is needed to process granular materials into fine powder. It is recommended that you choose a suitable mill according to the different discharge particle sizes.

CLIRIK YGM series grinding mill: 613-33 micron(30-325 mesh); D90=30 micron

CLIRIK HGM series ultra fine powder grinding mill: 74-5 micron(200-2500 mesh); D97=5 micron

CLIRIK CLUM series ultra fine verital roller grinding mill: 20-5 micron(600-3000 mesh); D50=2 micron D97=4 micron

10. Main unit classifying

The grading system can collect the powder that meets the requirements.

According to the number of classifier outlets, it can be divided into

single-head classifier,

double-head classifier, and

multi-head classifier.

11. Pipe conveying

Qualified powder must be transported to the dust collector through the pipeline.

12. Pulse bag filter powders collection

The pulse dust collector is mainly composed of upper box (clean air chamber), middle box (dust air chamber), ash hopper, pulse cleaning system, filter bag, filter bag skeleton, air inlet and outlet, differential pressure gauge, maintenance manhole, unloading Ash device, and pLc controller, etc.

The pulse bag filter is driven by the fan power, and a negative pressure environment is formed inside the dust collector, the dust removal pipe and the dust removal cover mouth, so that the dust at the dust point enters the dust collector under the action of the pressure difference, and the dust-containing gas enters the dust removal through the air inlet After the filter, the airflow speed slows down, the coarse particles leave the airflow and settle into the dust collection chamber. The fine dust is blocked on the outer surface of the bag when the airflow passes through the bag, and the clean gas is discharged from the air outlet

13. Finished powders transporation

14. Packaging

15. Compressed air transporation system

Compressed air system means that air at atmospheric pressure is compressed and delivered to the pneumatic system at a higher pressure.

The

air compressor is used to achieve the purpose of compressing air.

16. Power remote control system

17. PLC central control system

Shanghai CLIRIK Machinery Co.,Ltd. provides a complete set of milling solutions.

Contact CLIRIK now to get your exclusive ultra-fine powder grinding design plan!

Email: sales@clirik.com

WhatsApp: +8613512155195/+8613917147829