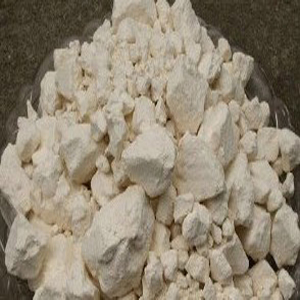

The mill equipment can process pure kaolin, and then apply it in all walks of life. The pure kaolin clay has high whiteness, soft quality, easy to disperse and suspend in water, good plasticity and high cohesiveness, excellent The electrical insulation performance; has good acid solubility, very low cation exchange capacity, better fire resistance and other physical and chemical properties.

Therefore, kaolin clay has become a mineral raw material required by dozens of industries such as papermaking, ceramics, rubber, chemicals, coatings, medicine and national defense. Kaolin is widely used in the paper industry. There are two main areas, one is the filler used in the papermaking process, and the other is the pigment used in the surface coating process.

China is a large coal-producing country. Basically, large coal mines are associated with coal-measure kaolin, so the coal-measure kaolin reserves are very rich. The proven industrial reserves of non-coal kaolin in 1996 were 1.432 billion tons. Compared with other non-metal resources, kaolin is not a superior resource in China, and it is even more in short supply if calculated per capita. Moreover, the distribution of China's kaolin resources is relatively scattered, and the grade is not high. Most of them are coal-based kaolins, which need to be calcined or modified, and they have natural limitations when used in papermaking.

Shanghai CLIRIK Machinery Co., Ltd. specializes in the production of various

ore mills, including calcite mills, dolomite mills, mica powder mills, kaolin mills, and phosphate rock mill machines, limestone mills, etc. Our grinidng equipment is energy-saving, environmentally friendly and clean, and the fineness and output of each equipment can be manually adjusted.

The

Raymond Kaolin Mill is widely used in industry and is suitable for processing most of the ore. The fineness of the product varies between 250-325 mesh. The fineness and output of the product can be adjusted during operation.

1. Kaolin clay Raymond Mill adopts the advanced structure of similar foreign products, and is updated and improved on the basis of large Raymond Mill.

2. The kaolin Raymond mill is more efficient than ball mills, has lower power consumption, smaller floor space, and less one-time investment.

3. The grinding roller is tightly pressed on the grinding ring under the action of centrifugal force, so when the grinding roller and grinding ring are worn to a certain thickness, the output and fineness of the finished product will not be affected.

4. The grinding roller and grinding ring have a long renewal cycle, thus eliminating the shortcomings of the centrifugal crusher's short replacement cycle for wearing parts. The air separation air flow of this machine circulates in the fan-the mill shell-the cyclone separator-the fan, so it has less dust than the high-speed centrifugal mill, and the operating workshop is clean and the environment is pollution-free.

5. Kaolin Raymond pulverizer The whole Raymond mill is a vertical structure with a relatively small footprint and strong system. It can be self-contained from rough processing of raw materials to conveying to powder making and final packaging. An independent production system.

6. Compared with other milling equipment, Raymond kaolin mill has a high pass-through rate, which is as high as 99%, which is generally not achieved by other milling equipment.

7. The main transmission device of the kaolin Raymond mill adopts a closed gear box and belt wheel, which is stable in transmission and reliable in operation.

8. The important parts of the kaolin Raymond mill are made of high-quality castings and profiles. The craftsmanship and rigorous process ensure the durability of the whole set of equipment.

9. The electrical system of the kaolin Raymond mill adopts centralized control, and the milling workshop can basically realize unmanned operation and maintenance.

After years of practice and continuous improvement, the CLIRIK Kaolin Raymond Mill has become more and more perfect in structure. It has the advantages of high efficiency, low energy consumption, small footprint, low capital investment and no environmental pollution. Therefore, it is widely used in the grinding and processing of mineral materials in the fields of metallurgy, building materials, chemicals, mining, etc. It is suitable for processing non-flammable and explosive minerals with Mohs hardness below seven and humidity below 6%.

In addition to the kaolin clay Raymond grinding mill, CLIRIK also introduced vertical mills, micro powder grinding mills , coarse powder grinding mills and other kaolin clay processing machines with different functions and prices for the requirements of 30-3000 mesh kaolin powders. Welcome to call or online leave a message.

Email: sales@clirik.com

WhatsApp: 008613917147829/ 008613512155195