Bentonite

Bentonite is a water-bearing clay mineral mainly composed of montmorillonite.

The chemical composition of montmorillonite is: (Al2, Mg3) Si4O10 OH2·nH2O, due to its special properties. Such as swelling, adhesiveness, adsorption, catalytic, thixotropy, suspension and cation exchange.

Therefore, it is widely used in various industrial fields.

The montmorillonite structure of bentonite is a 2:1 type crystal structure composed of two silicon-oxygen tetrahedrons and a layer of aluminum-oxygen octahedron.

Due to the layered structure formed by the montmorillonite unit cell, there are certain cations, such as Cu, Mg , Na, K, etc., and the effect of these cations with the montmorillonite unit cell is very unstable and easily exchanged by other cations, so it has good ion exchange.

Foreign countries have been applied in more than 100 departments in 24 areas of industrial and agricultural production, and there are more than 300 products, so people call it "universal soil."

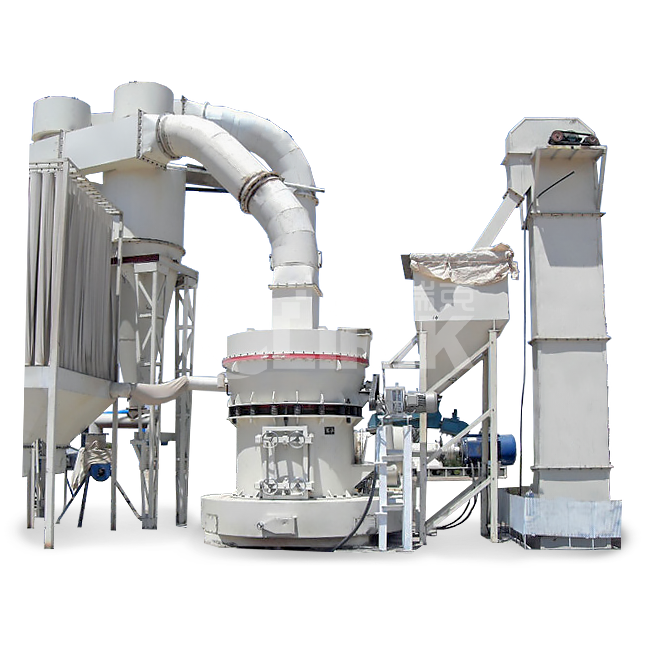

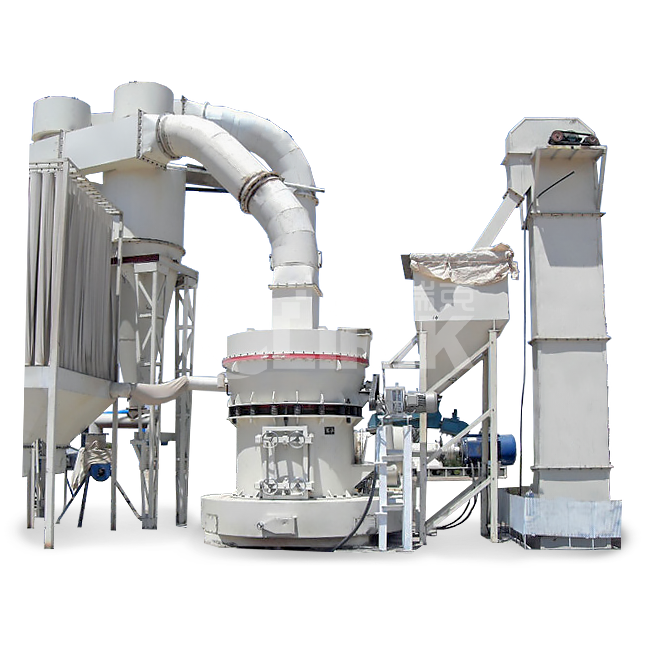

Bentonite powder process flow

The application range of bentonite in modern industry is becoming more and more extensive, so the demand for bentonite is also increasing. Of course, the production of bentonite requires the use of grinding mills.

The physical properties of bentonite are quite different. Therefore, the characteristics of bentonite are constantly expanding in various fields. This has further improved the requirements for bentonite grinding equipment. Of course, the improvement of grinding efficiency will lead to mineral resource saving and energy saving. An important part of low-carbonization. So how to choose the right bentonite grinding mill for different fineness requirements?

Bentonite Raymond Mill- powder fineness less than 400 mesh

When processing bentonite between 100 mesh and 300 mesh, the most suitable bentonite grinding equipment is Raymond mill;

After the bentonite is produced by Raymond mill grinding, sometimes the processed bentonite is large or small. Competent manufacturers can use screening machines to screen, and most users sell bentonite directly.

If you want to pulverize bentonite, you need to enter the mill for primary crushing.

The so-called primary crushing is to set up a crushing device before entering the pulverizer. Most of these crushing devices are jaw crushers. The bentonite is crushed into a size suitable for the Raymond mill feed, and it is pulverized to the required fineness in the Raymond mill.

Bentonite micro powder mill- powder fineness 325 mesh to 2500 mesh

Micro-powder mills should be used when the mesh is above 800 mesh, because this type of equipment is a high-yield, low-energy-consumption, low-maintenance milling equipment, and is the best bentonite mill.

After being crushed by the hammer crusher, the large bentonite material becomes small particles, which are sent to the storage hopper by the elevator, and then sent to the middle of the first dial by the electromagnetic vibrating feeder and the feeding tube evenly.

The bentonite particles are pushed to the edge of the dial under the action of centrifugal force, fall into the ring, pulverized by grinding rollers, and after passing through three to four layers of grinding rings, they are ground into bentonite powder.

The high-pressure centrifugal fan sucks in outside air and blows the crushed bentonite powder to the classifier.

The rotating turbine in the classifier makes the coarse bentonite powder return to the mill for re-grinding, and the fine bentonite powder is mixed with air into the cyclone separator and discharged in the discharge bin located at the bottom of the cyclone separator.

Mixed with extremely fine air, after being purified by pulse dust collector, it is discharged by blower and muffler.

Bentonite application field

Bentonite ore is a kind of mineral with multiple uses. Its quality and application fields mainly depend on the content and attribute type of montmorillonite and its crystal chemical characteristics.

Therefore, its development and utilization must vary from mine to mine and from role to role.

Such as the production of activated clay, calcium-based to sodium-based, drilling grouting for petroleum drilling, instead of starch for spinning, printing and dyeing slurry, interior and exterior wall coatings for building materials, preparation of organic bentonite, and synthesis of 4A zeolite with bentonite. White carbon black and so on.

1. Bentonite has adsorption and cation exchange properties, and can be used to remove toxins from cooking oil, purification of gasoline and kerosene, and wastewater treatment;

2. Because of its good water swelling performance, dispersion and suspension and slurry-making properties, it is used for drilling mud, flame retardant (suspended fire extinguishing);

3. It can also be used as fillers in the paper industry to optimize coating properties such as adhesion, hiding power, water resistance, and scrubbing resistance;

4. Because of its good cohesive force, it can replace starch for yarn sizing in the textile industry. It saves food and does not fluff, and it does not emit any peculiar smell after the paddle, which is really a double effect.

5. Bentonite can also be used as waterproof material, such as bentonite waterproof blanket, bentonite waterproof board and supporting materials, which are laid by mechanical fixing method.

Shanghai Clirik Machinery Co.,Ltd. specializes in the production of bentonite grinding equipment. The CLIRIK bentonite grinding production line has increased the output by 10% compared with other production equipment. The whole process is closed, pollution-free, and reaches international standards. It has provided technical support for hundreds of bentonite processing plants at home and abroad.

You can leave a message online or contact CLIRIK directly:

Email: sales@clirik.com

WhatsApp: +8613512155195/+8613917147829