Carbon Balck From Waste Tyre

Carbon Balck From Waste Tyre also named Wet Carbon Black, Regenerated Carbon Black, Ultrafine Powder Carbon Black, Modified Carbon Black and Thermal Black

Modified Carbon Balck Introduction:

There are some differences in production methods between Modified Carbon Black and Traditional Carbon Black.

Modified Carbon Black is the product by the effects of pyrolysis techology from waster tyre.

With the main materials of silica, cobalt salts and zinc, it is unique in chemical and physical performance that can possess better degree of crosslinking and diffusivity.

Thermal black is a kind of new rubber strengthening agent which is generated through pyrolysis technology.

It is processed by using old tires as raw materials, and in the condition of absence of stripping and the negative pressure through pyrolysis technology.

Because the production method of thermal black is different with the traditional carbon black production method, the performance of it is similar with the semi-reinforcing black, which is between N330 and N660.

It can improve the mechanical properties of rubber and enlarge the filing quantity because of small particle size and large surface area.

Also the price is low. And it can be applied to all kinds of tires, plastic board and other rubber products.

It can take the place of semi-reinforcing, and much better mix with the super high wear-resisting products.

This product which polymeric rubber compounds through catalytic cracking and removing carbony/hydroxy functional group and then activate is a kind of high performance and new semi-reinforcing carbon black.

Advantages of Thermal Black

Thermal Black is bright coloured.

Performance of Thermal Black

It could substitute other carbon black, such as general carbon black, low structure and fast extruding black, and semi-reinforcing black. Through micro adjusting the formula, cost will be greatly reduced. The physical properties of this product is close to N660 type.

Purpose of Thermal Black

In the aspect of rubber molding, such as the extrusion of cover tyre, mat tyre, inner tube, hose and automotive sealing strip, the semi-finished product has good stiffness, smooth surface, stable quality and superior performance. AIll this advantages bring good reputation from users.

In addition to keeping good quality, manufacturers also could reduce the comprehensive cost by 5% to 10% to obtain remarkable economic benefit by using pyrolytic carbon black in rubber and plastic products. They could save a part of softener, reduce power consumption, and eliminate mixed burning phenomenon in the process of producing. In addition, pyrolytic carbon black are widely used in cable, tape, rubber hose, gaskets, seals and other rubber products.

The Normal Application Of Thermal Black:

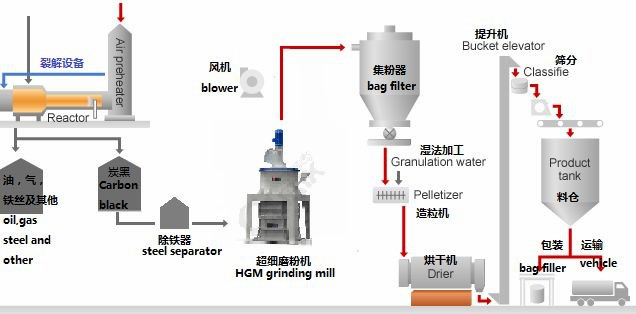

The carbon black come out from Pyrolysis equipment,the fineness is about 40-50mesh,it can be sold directly with low valve,but most of clients want to do deep processing for this carbon black for higher valve,so they need grinding mill to grind the powder to be 100-2500mesh, also the iron in it can be moved out by steel separator.

This carbon black not only has the advantage of filling and reinforcing effects, but also can improve the uniformity of carbon black dispersion of rubber compounds and the processing functions of semi-finished rubber products. Thermal Black has been applied to some rubber compounds, such as inner fabric glue, outer fabric glue, sidewall rubbers, rubber lining layer, inner liner compound of radial tyres and inner tube compounds etc.,which will not impact the product quality with the adjustment of other compounding ingredients for above-mentioned rubber compounds. What's more, Modified Carbon Black are also widely used in cable,tape, sealing elements, and other rubber products.

Shanghai Clirik Machinery Co.,Ltd. has been researching the carbon black grinding mill for more than 10 years,now we already have many successful projects in USA,Poland, Turkey,China,India and so on.

CLIRIK HGM series micro powder grinding mill can grind the carbon black powder to be 100-2500mesh, adjusted any fineness you want.After survey the market and got many feedback from our clients, the application summary has been made below(only a few examples can be showed):

What are the uses of carbon black?

1. 50~200mesh, can be used as fuel in the heating system.

2.200~300mesh, can be pelleted as ball, used as air deodorant, waste water processing,etc.

3.200~ -800mesh, can be used in Rubber industry, such as cable, rubber products (like mud cushin....it can improve rubber quality, enhance abrasive resistance and hardness. (Popular)

4.800~1500mesh, high grade carbon, used as N330, N600, can directly sell in the market as active agent. (Popular and high value)

5.1000~2000mesh, higher grade, used in painting industry, in our daily life, the pen ink, print ink, used such powder as raw material. High value

6.3000~4000mesh, highest grade, used in tyre making as the raw material. Purity should be about 99.99%.

HGM Grinding Mill for Carbon Black Powder Making

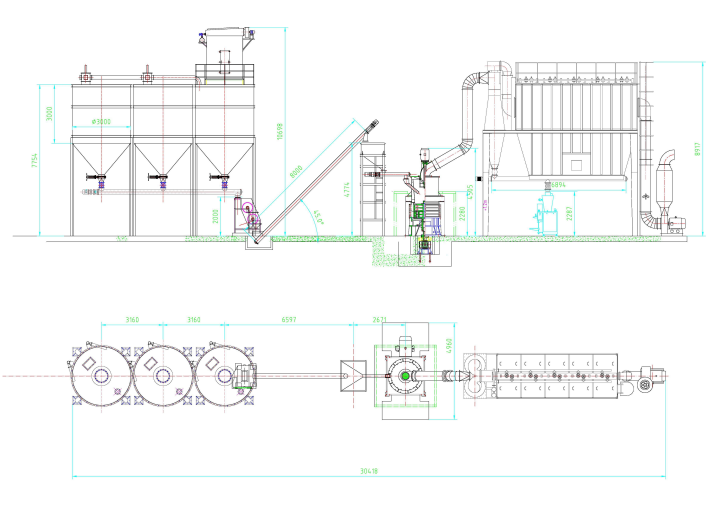

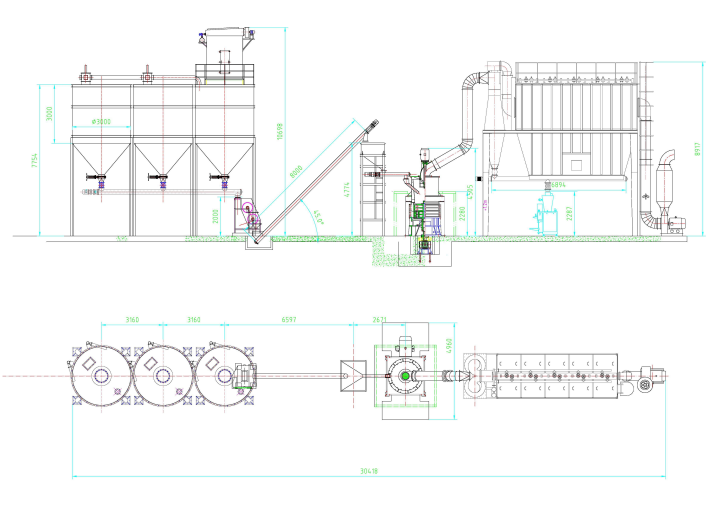

Our company designed and produced HGM series superfine mill, which are best for carbon black micro powder processing. Please see below standard carbon black processing plant, and we' d like to introduce the workflow:

The Working Principle Of Thermal Black Processing Plant

1. After pyrolysis, carbon black is a lttle hot; we put them in big silos, and let it cool down.

2. Use screw conveyor to send them into magnet separator machine.

3. After removing the iron parts, carbon black will go into feeding hopper (with cover), carbon black is very dark and sticky, and we must keep all tubes completely sealed.

4. Use screw feeder to put them into milling room.

5. With centrifugal force, it will fall down and be grinded roller between roller and ring.

6. Blower produces negative wind, which absorbs the powder and make it go through the classifier

7. Classifier is integrated in the grinder room, it is turning fast, the speed is controllable, so we can select the size we need. The big one will fall down and grind again.

8.70% powder will go into collector, and the rest will go into filter bag house with airflow.

9. All powder will be discharged from valve and packed into bags.

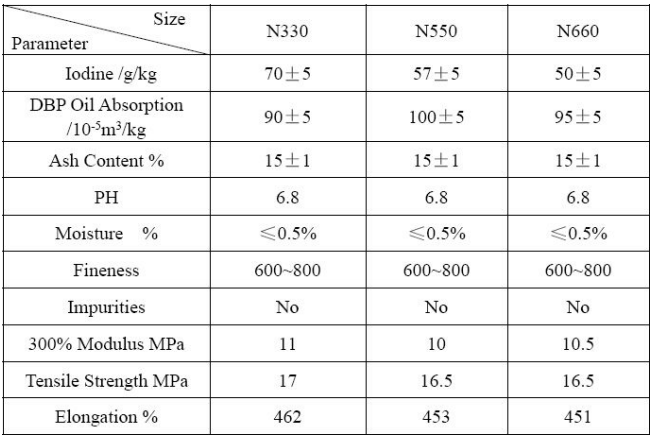

N330,N550,N660

Many clients want to make N330,N550,N660 with processing carbon black powder,which come out from pyrolysis. For N330,N550,N660, different country has different standard with different price. The ash content is one of influence factor of the carbon black valve,which is about 15% after come out from pyrolysis. So far, no one in the world has a perfect way to move ash into the powder, but China clients has a simple way to reduce the ash content.(can not showed here),now let me introduce the composition of N330,N550,N660 in China:

(Remark: the above parameter come from the N330,N550,N660 suppliers, as for N121,N134, N220,N234.etc. We didn't know about the detailed parameter)