Clirik

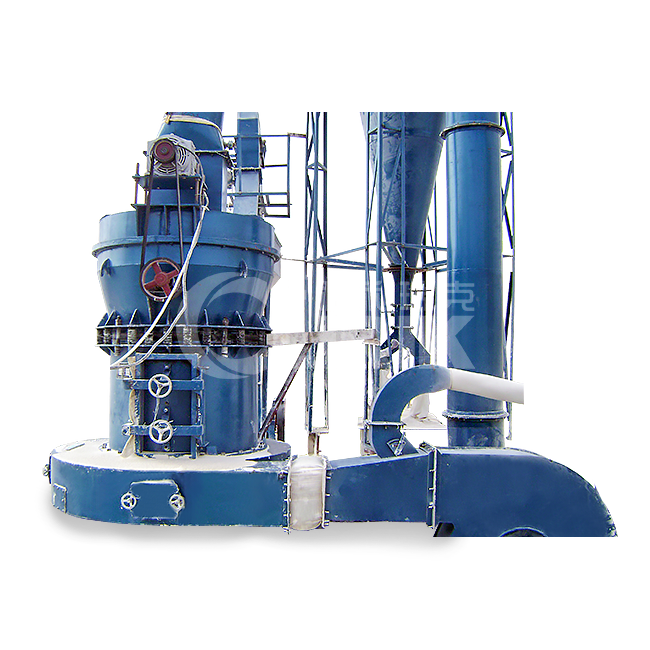

Raymond Mill is suitable for crushing barite, limestone, ceramics, slag and other non-flammable and explosive mines, metallurgy, chemical industry, building materials and other industries with a Mohs hardness of no more than 7 grades and a humidity below 6%. The high-fine powder processing of the materials, the finished product size is adjusted in the range of 50-450 mesh (the finest 1000 mesh). A 30-80 mesh coarse powder can be produced by adding special equipment inside the machine.

Raymond mills are sometimes referred to as high-efficiency grinding mills, suspension roller mills or ore grinding equipment.

Clirik Raymond Mill Features

Systematic

The three-dimensional structure, small footprint, and complete set of components, from the block to the finished powder independently become a production system.

Finished fine powder standard high

The fineness of the finished powder is uniform, and the screening rate is 99%, which is difficult for other milling equipment.

Wear-resistant and smoother operation

The important parts are made of high-quality steel, the wear parts are made of high-performance wear-resistant materials, and the wear resistance of the whole machine is high. The machine transmission adopts the closed gear box and pulley, the transmission is stable and the operation is reliable.

Easy to operate

The electrical system adopts centralized control, and the grinding workshop can basically realize unmanned operation and convenient maintenance.