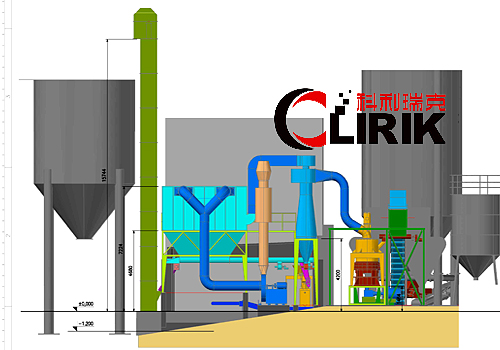

Overview of 2500 mesh grinding mill for bentonite:

Main Components of 2500 mesh grinding mill for bentonite:

HGM series

2500 mesh grinding mill for bentonite mainly consist of main unit, classifier, dust cleaner, powder collector, blower, muffler, hammer crusher (can be replaced by jaw crusher), bucket elevator, sound-proof room, storage hopper, vibrating feeder and so on.

Features of 2500 mesh grinding mill for bentonite:

1. The

2500 mesh grinding mill for bentonite is high efficient (twice as much as jet mill, mixing grinder and ball mill)

2. The spare parts of

grinding mill can serve much longer time (2-3 times longer than that of impact mill or turbo mill.

3. High safety and reliability of the

grinding mill (no rolling bearings and screws in the grinding cavity, so no problems caused by the wear of bearings or screws)

4. The

2500 mesh grinding mill for bentonite are characterized by high fineness (final size: 325-3000 mesh, D97<5 micron)

5. Environment-friendly.

Related information:

http://www.clirik.com/stone_grinding_mills/200.html